SDLG LG953 Loader 5-ton front-end wheel loader

LG953

Product Introduction

The LG953 is a long-wheelbase loader designed for handling bulk and hard materials. It combines the large breakout force and tipping load of a long-wheelbase loader with the flexibility and small turning radius of a short-wheelbase loader, making it versatile for various applications including sand plants, ports, construction sites, and mines.

The loader features a low-speed, high-torque Weichai engine that meets China II emission standards. This engine is known for its low fuel consumption, strong power, and high reliability. It includes a horizontally-mounted, two-stage air filter to enhance engine protection and performance.

The cooling system uses an electrically-controlled thermal energy management module and an optimized radiator structure with improved intake and exhaust ducts. These features effectively lower engine water temperature and hydraulic oil temperature, thereby improving overall cooling efficiency.

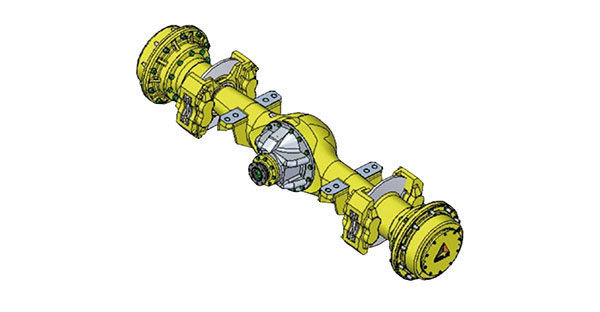

The loader is equipped with a sophisticated SDLG planetary transmission system, which includes two forward gears and one reverse gear. This setup ensures ease of operation, good reliability, and high efficiency. The drive axle is reinforced to handle large loads and provide reliable performance.

The new steel cab design offers drivers a wide field of vision and ample operating space. It features full-coverage interior components for better sealing and optional air conditioning for enhanced comfort.

The LG953 includes a digitalized stepping instrument panel developed by SDLG, which facilitates effective human-machine interaction and user-friendly operation.

The loader is equipped with a load-sensing, mechanically-controlled hydraulic steering system that offers easy control and stable performance. The hydraulic pipelines are double-sealed to ensure tightness and reliability.

Reinforced rear and front frames have undergone 200,000 cycles of fatigue testing. This testing ensures that the load distribution is optimized, contributing to high loading capacity and excellent stability.

The bucket is designed for optimal performance, with a trapezoidal wear-resistant steel cutting board and a thickened bottom wear-resistant plate. This design minimizes shoveling resistance and enhances the bucket's durability and wear-resistance.

Overall, the LG936L is a well-rounded wheel loader that delivers high performance and reliability across a range of applications, making it a valuable asset for any operation.

Product parameters

Rated bucket capacity |

1.8 m3 |

Minimum steering radius (outside of rear wheel) |

5381mm |

Rated carrying-capacity (kg) |

3000 |

Transverse passing radius (outside of bucket) |

6020 mm |

Maximum traction force (kN) |

≥105 kN |

altitude |

- |

Tipping load |

≥66 kN |

ambient temperature |

- |

Maximum breakout force |

≥96 kN |

wading depth |

- |

Forward I |

0~13 km/h |

Forward Ⅱ(km/h) |

0~38 km/h |

Forward Ⅲ(km/h) |

- |

Forward Ⅳ(km/h) |

- |

Reverse I (km/h) |

0~17 km/h |

Reverse II |

- |

Reverse III |

- |

Reverse IV |

- |

Overall length (mm) |

8000 |

Overall width (mm) |

3024 |

Outside width of wheel |

2845 mm |

Wheel track |

2250 |

Overall height (mm) |

3423 |

wheelbase(mm) |

3000 |

Dumping angle |

-45 |

Maximum dumping height |

3130 mm |

Number of axles |

2 |

Corresponding dump reach |

1220 |

Maximum lifting height of fork horizontal section(mm) |

- |

Total mass (kg) |

16900 |

Minimum ground clearance |

534 |

Axis pin at maximum lift height |

4125 mm |

Wheelbase (front/rear) (mm) |

- |

- |

- |

Engine model/Drive Motor Model |

WD10G220E21 |

Number of cylinders |

6 |

Engine type |

In line, water-cooled, four stroke, direct injection |

Bore/stroke |

126/130 |

Engine power (KW) |

162 |

Minimum fuel consumption |

215 |

Rated engine speed |

2200 |

Maximum torque (N.m)/rotation speed (r/min) |

860/1400~1600 |

Displacement (ml) |

9726 |

Emission standard |

GB 20891-2007 China II emission |

Type of torque converter |

Single-stage four-element twin turbine torque converter |

Torque ratio |

4.20 |

Oil cooling mode |

Circulating water cooling |

Oil pressure of torque converter inlet |

0.5~0.6 |

Oil pressure of torque converter outlet |

0.21~0.26 |

Transmission type |

Planetary power shift |

Shifting gears |

forward 2 reverse 1 |

Gear ratio of forward I |

2.547 |

Gear ratio of forward Ⅱ |

0.683 |

Gear ratio of forward Ⅲ |

- |

Gear ratio of forward Ⅳ |

- |

Gear ratio of reverse I |

1.864 |

Gear ratio of reverse II |

- |

Gear ratio of reverse III |

- |

Gear ratio of reverse IV |

- |

Model of variable-speed pump |

LG03-BSB |

Working pressure of shifting |

1.1~1.5 |

Main drive type |

First reduction of spiral bevel gear |

Main drive reduction ratio |

4.625 |

Wheel reduction type |

One-stage planetary reduction |

Wheel reduction ratio |

4.94 |

Drive type |

CHANGCHAI four-wheel drive |

Tyre size |

23.5-25 |

Front tyre pressure |

0.39±0.01 |

Rear tyre pressure |

0.33±0.01 |

Type of foot brake |

Air-over-oil caliper disc brake |

Brake pressure (MPa) |

0.784 |

Parking brake type |

Manual internal expansion shoe brake |

Type of steering system |

Load-sensing full hydraulic articulated steering |

Model of priority valve |

VLE-150S |

Steering pump model |

100/10 |

Steering cylinder - bore x rod diameter x stroke |

HSGL-90*45*360 |

Steering gear model |

Xcel80-800 |

Steering angle (°) |

35° |

Working pressure of steering system |

16 |

- |

- |

Type of working device |

Hydraulic pilot control |

Boom cylinder - bore × rod diameter × stroke |

HSGF-160*90*805 |

Turning bucket cylinder - bore x rod diameter x stroke |

HSGF-190*90*548 |

Model of working pump |

JHP3160S |

Displacement of working pump (ml/r) |

160 |

Model of multi-way valve |

DFSY-32-18 |

Model of pilot valve |

GDXS2-DT |

Working pressure of working device hydraulic system |

18 |

Bucket lift time (full load) |

≤5.4 |

Bucket fall time (no load) |

≤2.8 |

Bucket dumping time (no load) |

≤1.1 |

Time sum of three items |

≤9.3 |

Diesel filling capacity of fuel tank |

260 |

Oil filling capacity of axles (main drive and wheel reducer) |

26×2 |

Oil tank filling capacity |

240 |

Engine oil filling capacity |

20 |

Transmission oil filling capacity |

44 |

Refueling of antifreeze coolant |

55L |

Oil filling capacity of braking system |

4 |

- |

- |

GET FINANCING!

Grow Your Fleet & Increase Your Revenue

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

Spare Parts

Spare Parts