SDLG L938F Wheel Loader 1 cubic meter bucket

LG938L

Product Introduction

The LG938L is a high-end wheel loader designed for the efficient loading and unloading of loose materials, known for its versatility and reliability. This machine is widely utilized in a variety of settings, including construction sites, small-scale mining operations, aggregate plants, and municipal construction projects, where its robust performance and adaptability make it an invaluable asset.

Key Features and Specifications:

The LG938L is powered by a DEUTZ engine, imported directly from Germany in its original packaging. This engine meets the stringent Tier4i emission standards, ensuring strong power output combined with high reliability and environmental compliance. Additionally, the loader is equipped with post-processing equipment that includes an active regeneration function, further enhancing its environmental friendliness and operational efficiency.

The loader's cooling system is engineered for maximum efficiency and reliability. It features a radiator with an independent cooling system and a double-row parallel structure. The optimized terminal insulation design for the heat emission compartment, coupled with a hydraulic motor-driven fan, ensures effective cooling even under demanding conditions. The fan speed is automatically adjusted according to the system temperature, contributing to significant energy savings and maintaining high cooling efficiency throughout the operation.

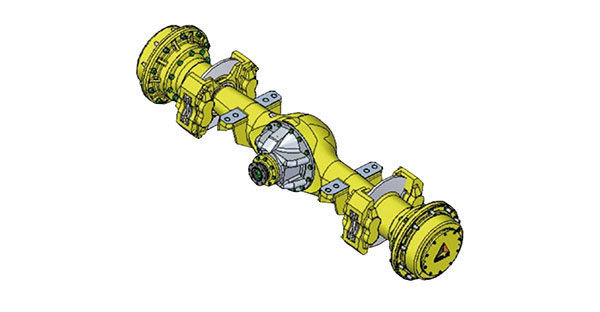

The LG938L utilizes a ZF axis-fixed electric-liquid shift transmission case, offering four front gear positions and three rear gear positions. This setup delivers high transmission efficiency and ensures smooth, comfortable operation. The loader is also equipped with an SDLG reinforced drive axle, which features a well-balanced front and rear axle load distribution, large bearing capacity, high reliability, and exceptional stability for the entire machine. These features are crucial for maintaining consistent performance in various working environments.

The entire machine incorporates SDLG’s specialized NVH (Noise, Vibration, and Harshness) technique, along with a three-stage damping system. This system includes a new damping seat that significantly enhances the operator's comfort by reducing vibrations and noise, making long hours of operation less fatiguing.

The LG938L is equipped with a FOPS/ROPS-certified cab, which provides wide visibility, fully-covered internal trimmings, and excellent sealing performance. The cab meets up-to-ISO-standard air conditioning requirements, ensuring a safe and comfortable working environment for the operator. For those who prefer a different setup, a standard cab option is also available. The attention to safety and comfort in the cab design is evident, making it an ideal workspace for operators in various conditions.

The loader is equipped with SDLG’s self-developed digitized stepping dashboard, which enhances human-machine interaction. The centralized control system for the electrical apparatus ensures convenient inspection and maintenance, contributing to the overall reliability of the electrical components.

The LG938L employs a load-sensing full hydraulic steering system, which includes an emergency steering function for added safety. This system is both energy-saving and highly efficient, making steering light and responsive. The pilot-control working device hydraulic system further enhances operational efficiency, offering smooth, precise control that is easy to handle. Additionally, the loader is equipped with a full hydraulic braking system, ensuring stable and reliable braking performance in various conditions.

The LG938L features an optimized design for the front and rear frames, with a focus on reasonable load distribution. The machine includes a steering soft limit to reduce impact, contributing to a smoother operation. The overall fatigue life of the machine is rated up to 8,000 hours, demonstrating its durability and reliability in demanding conditions. The hanging system utilizes a composite structure of tapered roller bearings and oscillating bearings, making the loader more adaptable to challenging operating environments.

Technical Parameter

Item |

Specifications |

Operating weight |

10500~10900Kg |

Bucket capacity |

1.8~2.5m³ |

Rated load |

3000Kg |

Max.breakout force |

96KN |

Max.dumping height(E) |

2800~3078mm |

Dumping distance(G) |

1050~1263mm |

Length×Width×Height |

7730 × 2520 × 3234 |

Max.tractive force |

105KN |

Max.climbing angle(H) |

30° |

Total time |

≤9s |

Steering angel(O) |

38° |

Tipping load |

66KN |

Rated power |

120kW |

GET FINANCING!

Grow Your Fleet & Increase Your Revenue

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

Spare Parts

Spare Parts