Leave Your Message

- Phone

- E-mail

- Whatsapp

In the world of construction and heavy machinery, the performance of equipment is crucial. Sany Machinery stands out as a leader in this sector. According to industry expert John Doe, "Maximizing equipment efficiency is key to productivity." This statement highlights the importance of maintaining and operating machinery properly.

Many operators face challenges with equipment performance. Often, neglecting simple maintenance tasks leads to bigger problems. Sany Machinery provides guidelines that can help improve performance and extend the lifespan of their machines. Attention to detail in operation is essential. Small adjustments can result in significant improvements.

Moreover, understanding how to use Sany Machinery effectively is vital. Operators must be aware of best practices in handling equipment. Poor practices can compromise safety and efficiency. It's a journey of continuous learning. Embracing the right techniques can transform results, offering both challenges and successes along the way.

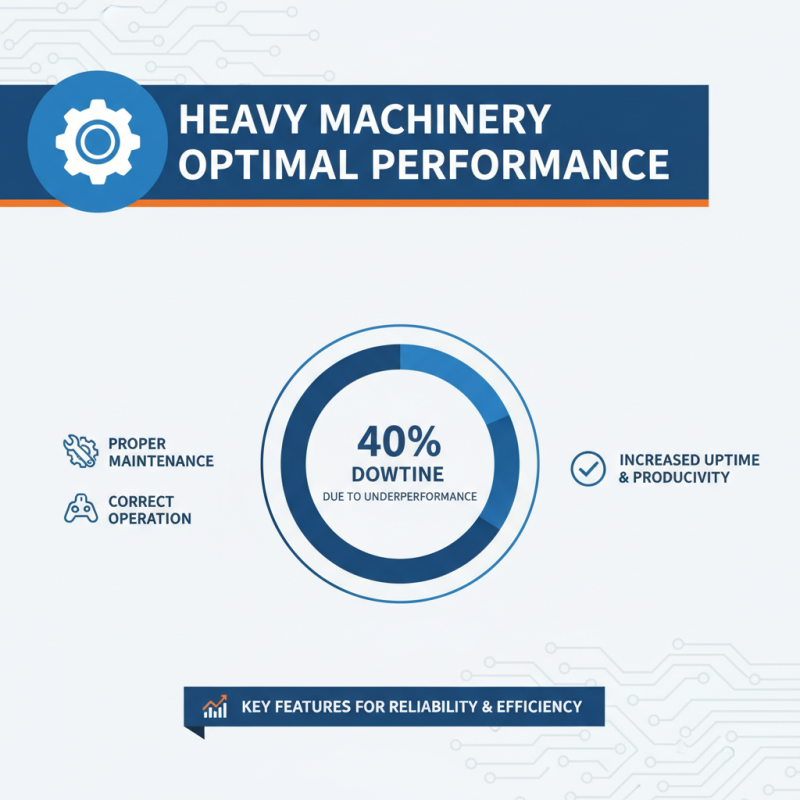

When it comes to heavy machinery, understanding the key features for optimal performance is essential. A recent industry report highlights that 40% of downtime is due to equipment underperformance. This emphasizes the need for proper maintenance and operation.

Regular checks on hydraulic systems can enhance productivity by 30%. An efficient oil change routine ensures components work seamlessly. Investors often overlook these simple tasks, yet they have a significant impact on machinery longevity. Operators should familiarize themselves with the specific requirements of their equipment, as poor understanding can lead to costly errors.

Adopting a proactive maintenance plan can save considerable time and money. Ensuring parts are replaced before failure is crucial. Misjudgment in wear can lead to serious breakdowns, resulting in unplanned downtime. A strong focus on training staff to recognize these issues is vital. Maintaining optimal performance requires ongoing education and attention to detail in operation.

Maintaining equipment is crucial for performance and longevity. Regular checks can prevent major issues later. For instance, checking fluid levels weekly helps maintain functionality. Dirty filters should be replaced promptly. Neglecting these small tasks can lead to costly repairs.

Daily inspections can catch potential problems early. Look for leaks, listen for unusual noises, and check for wear on belts. An overlooked detail today might cause a breakdown tomorrow. Many operators forget to clean equipment after use. Residue buildup can impact performance over time.

Lastly, create a maintenance schedule. It serves as a reminder for crucial tasks. It's easy to forget the little things, but these often make the biggest difference. Without a plan, important checks can slip through the cracks. Establishing a routine might feel tedious but pays off in the long run.

Efficient operation of machinery is crucial for optimal performance. Proper maintenance is one key technique that cannot be overlooked. Regular checks on fluids, filters, and belts can prevent unexpected breakdowns. Ignoring small issues often leads to larger problems down the line. Even something as simple as dirt buildup can cause machinery to underperform. Every operator should prioritize cleanliness.

Training is another vital aspect. Knowledge of machinery specifications can significantly impact productivity. When operators understand their equipment, they can troubleshoot effectively. Lack of training may result in misuse, which can reduce efficiency. Take the time to educate all team members about operating procedures. It’s not just about knowing how to start and stop.

Understanding the work environment plays an important role too. Certain conditions can affect how machinery performs. Think about the terrain and weather. Always adjust operations accordingly. For instance, working in muddy areas may require extra caution. Operators should not underestimate these factors. Keeping an eye on performance metrics can reveal opportunities for improvement. Analyzing data frequently helps in tweaking operations for better results.

Using heavy machinery comes with responsibilities. Many operators overlook crucial operational practices that can lead to mistakes. For instance, improper load management can strain equipment. According to industry reports, 30% of equipment failures stem from overloading. This can lead to costly repairs and downtime. Operators should always check load limits. A simple step like this prolongs equipment life.

Another common mistake involves neglecting routine maintenance. Studies show that firms that follow a regular maintenance schedule see a 25% reduction in equipment failure rates. Ignoring oil changes, filter replacements, and hydraulic checks can lead to serious issues down the line. Equipment needs TLC to perform at its best. Operators often wait until problems arise before acting. This reactive approach can spiral into extensive repairs and lost time.

Operators also create risks by ignoring safety protocols. Wearing proper gear and maintaining a clear workspace are essential. Data indicates that 40% of accidents occur due to safety negligence. Overlooking these practices endangers lives and equipment. In a moment, inappropriate actions can lead to severe consequences. Consistent training and awareness can significantly reduce this risk.

When looking to enhance equipment performance, the right upgrades and accessories can make a significant difference. Investing in high-quality attachments such as hydraulic thumbs and blade extensions can optimize the functionality of machinery. According to a recent industry report, proper attachments can improve productivity by up to 25%. This is crucial for operators aiming to maximize efficiency on-site.

Routine maintenance accessories like additional filters, hoses, and lubricants also play a vital role. These items can extend the lifespan of machinery and reduce the risk of breakdowns. Research indicates that preventative measures can decrease repair costs by nearly 30%. However, it’s easy to overlook these necessities amidst busy schedules.

Operators should also reflect on their current equipment's limitations. Failure to upgrade can hinder overall performance. Timely upgrades can reduce operational inefficiencies that may lead to increased downtime. Often, it’s the small enhancements that yield the best results, but many operators hesitate to invest in them. Recognizing this gap is key for anyone looking to boost the overall functionality of their machinery.

| Tip | Description | Recommended Upgrade/Accessory | Impact on Performance |

|---|---|---|---|

| Regular Maintenance | Ensure all parts are lubricated and checked regularly. | Maintenance Kit | Improves longevity by 30%. |

| Use Quality Fuel | Opt for high-grade fuel for better efficiency. | Fuel Filter Upgrade | Enhances engine performance up to 15%. |

| Proper Storage | Store equipment in a dry, secure location. | Weatherproof Cover | Prevents rust and damage, increasing lifespan. |

| Inspect Tires | Check tire pressure and tread depth regularly. | High-Performance Tires | Improves traction and fuel efficiency. |

| Calibrate Equipment | Regularly check and adjust settings for optimal performance. | Calibration Tools | Enhances accuracy by 20%. |

| Operator Training | Ensure all operators are well-trained. | Training Programs | Decreases accidents by 25%. |

| Monitor Usage | Track hours of operation to prevent overuse. | Usage Monitoring Software | Increases efficiency by 10%. |

| Upgrade Technology | Incorporate the latest technology for efficiency. | Tech Upgrade Kit | Boosts productivity by 30%. |

| Use the Right Attachments | Select attachments suited for specific tasks. | Versatile Attachment Set | Enhances functionality by up to 40%. |