Leave Your Message

- Phone

- E-mail

- Whatsapp

Earth moving equipment plays a critical role in various industries. It is a cornerstone of construction, mining, and infrastructure projects. According to the Global Construction Equipment Market Report, the earth moving equipment segment is expected to reach $192 billion by 2025. This rapid growth highlights the increasing demand for efficient machinery.

These machines, including excavators, bulldozers, and backhoes, significantly boost productivity. For instance, an excavator can dig deep trenches faster than manual labor. Such efficiency translates into cost savings and timely project completion. However, the industry faces challenges. Many operators lack proper training, which can lead to safety incidents. Data from OSHA indicates that improper operation accounts for 30% of equipment-related accidents.

The essential uses of earth moving equipment extend beyond just moving soil. They reshape landscapes and support vital infrastructure development. With advanced technologies like GPS tracking and automation, these machines are becoming smarter. However, the environmental impact of heavy machinery should not be overlooked. Companies are learning to balance productivity with sustainability. This reflection on practices is necessary for a better future in earth moving operations.

Earth moving equipment is vital in construction and excavation. These machines help shape the land for various projects. Common types include bulldozers, excavators, and backhoes. Each serves a unique purpose, maximizing efficiency and productivity.

Bulldozers are powerful and capable of pushing large amounts of soil. They tackle tough terrain and help clear sites. Excavators excel at digging deep holes and trenches. Their rotating arm offers precision, making them essential for foundation work. Backhoes combine a loader and a digger in one machine. They are versatile and efficient for smaller jobs.

Understanding the specifics of earth moving equipment is crucial. Operators should know the right machine for different tasks. Misuse can lead to delays and safety hazards. Knowledge is key to optimizing resources and achieving project goals. Every piece of equipment has strengths and weaknesses. Recognizing these can prevent costly mistakes in the long run.

Earth moving equipment plays a crucial role in construction and excavation projects. Understanding the common types can help in effective project planning. Excavators are one key type. They are versatile, capable of digging, lifting, and shifting heavy materials. Statistics indicate that excavators account for approximately 40% of all earth-moving machinery used today.

Another essential type is the bulldozer. This powerful machine is designed for pushing large quantities of soil, gravel, or other materials. In many projects, bulldozers can significantly reduce time and labor costs. Reports show that using a bulldozer can increase site preparation speed by at least 30%. Yet, their operation requires skilled operators to avoid ineffective use and wastage.

Skid steer loaders are also common in the industry. Their compact design makes them ideal for confined spaces. They are often used for grading and landscaping tasks. Data reveals that they can enhance productivity by around 25%. However, they may struggle with heavy lifting jobs. It’s important to assess the right type of equipment for the job at hand. Many projects fail to do so, resulting in delays.

Excavators are crucial in construction and demolition. They are designed for digging, lifting, and moving heavy materials. With a rotating cab, they can access hard-to-reach areas. The long arm can reach deep into trenches or heavy piles of dirt. This versatility makes them essential on job sites.

Bulldozers, on the other hand, excel in pushing and grading. They have a powerfully wide blade at the front. This blade allows for smooth earth-moving even in rugged terrains. Bulldozers are key for site preparation. However, they can disturb the natural environment significantly. Operators must frequently assess the impact of their work.

While these machines are efficient, they come with challenges. Correct operation is necessary to avoid accidents. Training for operators is vital but often overlooked. Machine maintenance can also be neglected. This neglect can lead to costly repairs. Understanding these aspects can enhance performance and safety on the job.

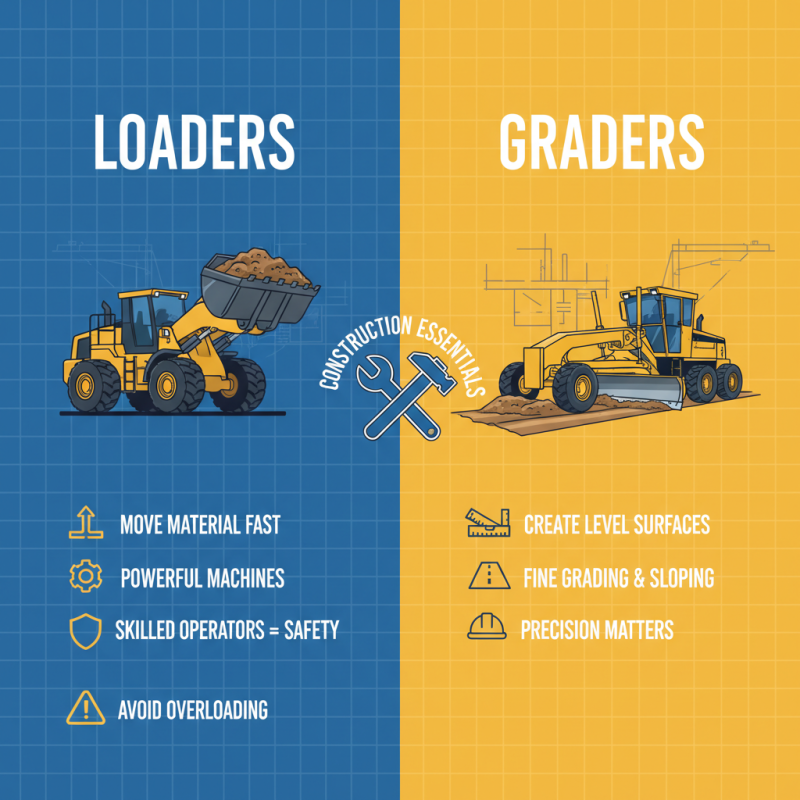

Loaders and graders play crucial roles in construction projects. Loaders are powerful machines. They excel at moving large volumes of material quickly. Their bucket can lift dirt, gravel, and debris with ease. Skilled operators can maneuver them in tight spaces. However, overloading a loader can lead to a breakdown. Proper training is essential to maximize efficiency and safety.

Graders, on the other hand, are designed for precision work. They create a smooth surface for roads and foundations. The blade can be adjusted to achieve the desired grade. An operator's experience makes a significant difference in the outcome. It's essential to check the machine's angle regularly. If not done, it may result in uneven surfaces.

Both loaders and graders are indispensable in construction. Investing time in training operators can enhance productivity. However, machines alone cannot guarantee success. Attention to detail is necessary for optimal results. Mistakes can be costly, but they offer learning opportunities.

Choosing the right equipment for a construction project is crucial. Each project has its unique demands. The equipment must match the task to achieve efficiency. For instance, excavators are commonly used for large-scale digging. They excel in trenching and removal of debris. However, they might not be suitable for smaller sites.

Bulldozers are another essential type. They move large quantities of earth quickly. Their wide blade can clear land in a matter of hours. But, they require ample space to operate effectively. If you're working in tight areas, a smaller machine might be needed. Choosing the wrong equipment can lead to delays and increased costs. It’s important to evaluate the project site carefully before making decisions.

Telehandlers can be versatile as well. They lift materials to various heights. However, they can be intimidating for new operators. Training is essential. Having the right operator is just as important as choosing the right machine. Take time to assess skills when staffing the project. Mistakes can happen if the crew is inexperienced.

This chart illustrates the various types of earth moving equipment and their primary uses across different types of construction projects.