Leave Your Message

- Phone

- E-mail

- Whatsapp

In the world of construction, Earth Moving Equipment plays a vital role. Experts like John Smith, a renowned industry leader, emphasize its importance, stating, "The right equipment can make or break a project." Understanding these tools is essential for success.

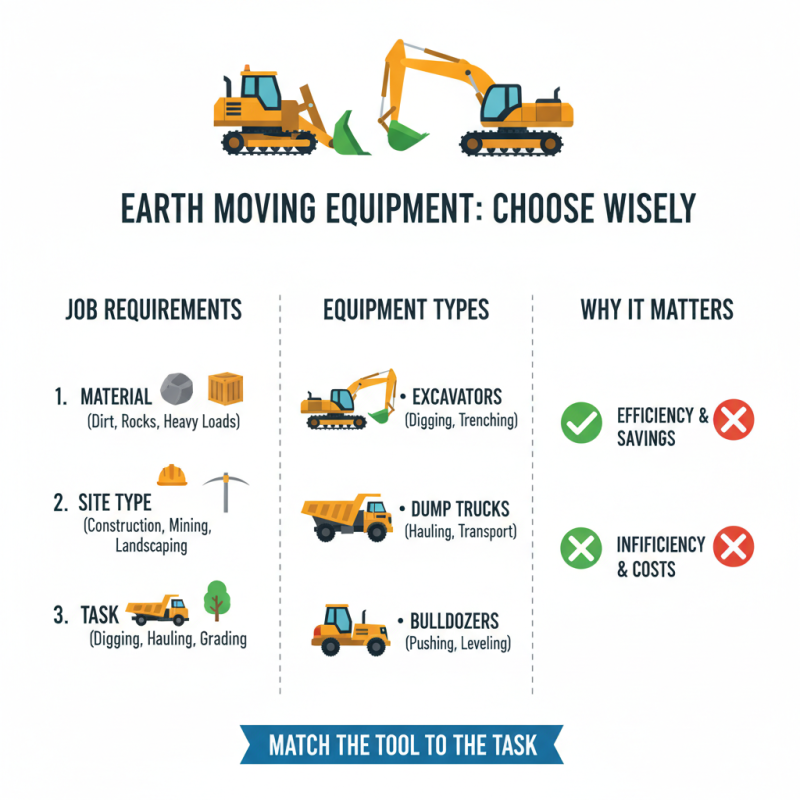

From bulldozers to excavators, each machine serves a unique purpose. These machines are powerful yet complex. Choosing the right equipment requires careful thought. Improper selection can lead to delays. It's crucial to assess the job site and project requirements.

In this guide, we will explore the top ten Earth Moving Equipment options. Each piece of equipment has strengths and weaknesses. The choices can feel overwhelming, even for seasoned professionals. Reflecting on these options can lead to better decision-making. Let's delve into the critical tools you need to know.

Earth moving equipment is essential for construction and excavation projects. Different types serve specific purposes, making them crucial in earthwork operations. Excavators are versatile machines designed for digging deep trenches. They are equipped with a bucket and can rotate 360 degrees, allowing for efficient material movement.

Bulldozers push large amounts of earth and debris. Their sturdy blades can clear paths quickly. Loaders, on the other hand, scoop and transport materials like soil, gravel, or sand. These machines are ideal for loading trucks or filling in holes. Keep in mind that operating heavy equipment requires skill and training.

**Tip**: Always check equipment specifications before use. Ensure the operator is experienced to minimize risks.

Another key type is the backhoe. It combines a digging arm with a loader, providing flexibility. Graders are used for leveling surfaces, crucial for road construction. Be aware that using the wrong equipment can lead to safety hazards.

**Tip**: Regular maintenance can extend equipment life, reducing costs in the long run.

In any project, understanding each machine’s function is vital for efficiency. Consider the terrain and material type before choosing the right equipment. Make informed decisions to avoid delays and complications.

When choosing earth moving equipment, consider the job’s requirements carefully. Not all projects are the same. Different tasks need different tools. Are you moving dirt, rocks, or heavy loads? Understanding the specific needs of your site can guide your choice. Too often, people select equipment without considering its purpose. This can lead to inefficiencies and increased costs.

Another important factor is the equipment's maintenance needs. Heavy machinery requires regular upkeep. Look for models that are easy to maintain. Complicated machinery can lead to delays. You want equipment that workers can fix quickly or operate with confidence. Also, pay attention to safety features. Equipment should include basic safety measures to protect users. Missing safety features can be disastrous.

Finally, think about the size and weight of the equipment. Larger machines can do more work but they often require more space. Can your site accommodate this? Overestimating equipment capabilities can cause problems later. It’s essential to match machine size to site dimensions. Pay attention to site accessibility and worker comfort, too. A comfortable work environment increases productivity. Consider all these elements to make a well-rounded decision.

Operating earth moving equipment requires strict adherence to safety practices. Proper training is vital. All operators must understand their machinery. This knowledge helps prevent accidents. Safety gear should always be worn. Hard hats, gloves, and steel-toed boots protect against injuries. Be aware of your surroundings. Blind spots can hide obstacles or other workers.

Before starting any machine, do a routine check. Look for leaks or loose parts. This simple step can reveal problems early. Always secure loads properly. An unbalanced load can lead to tipping. Maintain clear communication with crew members. Use hand signals or radios for clarity. In emergency situations, quick decisions are crucial.

There are times when safety protocols may be overlooked. Fatigue can lead to mistakes. Operators need breaks to stay alert. Reflecting on past issues is essential. Learning from mistakes creates a safer work environment. Safety is not just a checklist; it’s a culture that must be embraced.

Maintaining earth-moving equipment is crucial for longevity. Neglecting regular checks can lead to severe problems. Small issues can escalate quickly if not addressed. Clean your machinery often to avoid dirt buildup. Dust and grime can cause parts to wear prematurely.

Check fluid levels regularly. This includes oil, hydraulic fluid, and coolant. Low levels can lead to overheating, resulting in costly repairs. Keep an eye on tire pressure, too. Under-inflated tires can cause uneven wear and affect fuel efficiency.

Remember to inspect the tracks and pins on excavators and bulldozers. Lubrication is vital. Lack of grease can lead to early failures. Track alignment should also be monitored consistently. Misalignment can create extra strain on machinery, leading to increased maintenance needs. Treat your equipment with care, and it will serve you well for years.

| Equipment Type | Purpose | Maintenance Tip | Lifespan (Years) |

|---|---|---|---|

| Excavator | Digging and lifting | Regular oil changes and hydraulic fluid checks | 10-15 |

| Bulldozer | Moving large quantities of material | Check and adjust track tension | 10-20 |

| Loader | Loading materials into vehicles | Inspect bucket for wear and tear | 8-12 |

| Backhoe | Excavating and lifting | Lubricate points and hydraulic components | 10-15 |

| Skid Steer | Versatile for multiple tasks | Regularly check tire pressure | 5-10 |

| Dump Truck | Transporting large loads | Inspect the hydraulic system regularly | 10-15 |

| Paver | Laying asphalt | Keep the auger clean and lubricated | 8-12 |

| Compactor | Soil and asphalt compaction | Check the vibratory system regularly | 5-10 |

| Forklift | Lifting and transporting materials | Inspect safety features and battery life | 7-12 |

| Grader | Leveling and grading surfaces | Check blade and scraper for wear | 10-15 |

The earth moving equipment industry is evolving rapidly. New technologies are shaping how we approach construction and excavation. One significant area of innovation is automation. Machines can now operate with minimal human guidance. This increases efficiency but also raises questions about workforce impact.

Another exciting development is the use of electric power. Traditional diesel engines are being replaced. Electric equipment reduces emissions and operational costs. However, the infrastructure for charging these machines is still underdeveloped. Sector stakeholders must balance sustainability with practicality.

Data analytics is also changing the game. Advanced sensors collect performance data in real time. Operators can make informed decisions quickly. Yet, data security concerns linger. The reliance on technology demands a cautious approach. Changes are promising but require careful implementation.