Leave Your Message

- Phone

- E-mail

- Whatsapp

Maintaining the efficiency and longevity of your Hitachi Excavator is crucial for optimal performance on any job site. An excavator is a significant investment, and ensuring that it operates at its best can have a direct impact on productivity and operational costs. Proper maintenance not only helps prevent costly breakdowns but also extends the life of the equipment, allowing operators to maximize their return on investment.

In this guide, we will explore ten essential tips for maintaining your Hitachi Excavator. These practices are designed to enhance both performance and durability, from routine inspections to more intricate maintenance tasks. By following these guidelines, operators can ensure that their excavators remain reliable and efficient, paving the way for successful project completions and reduced downtime. Whether you are a seasoned professional or a new operator, understanding the intricacies of maintaining your equipment will serve as a cornerstone for achieving long-lasting results.

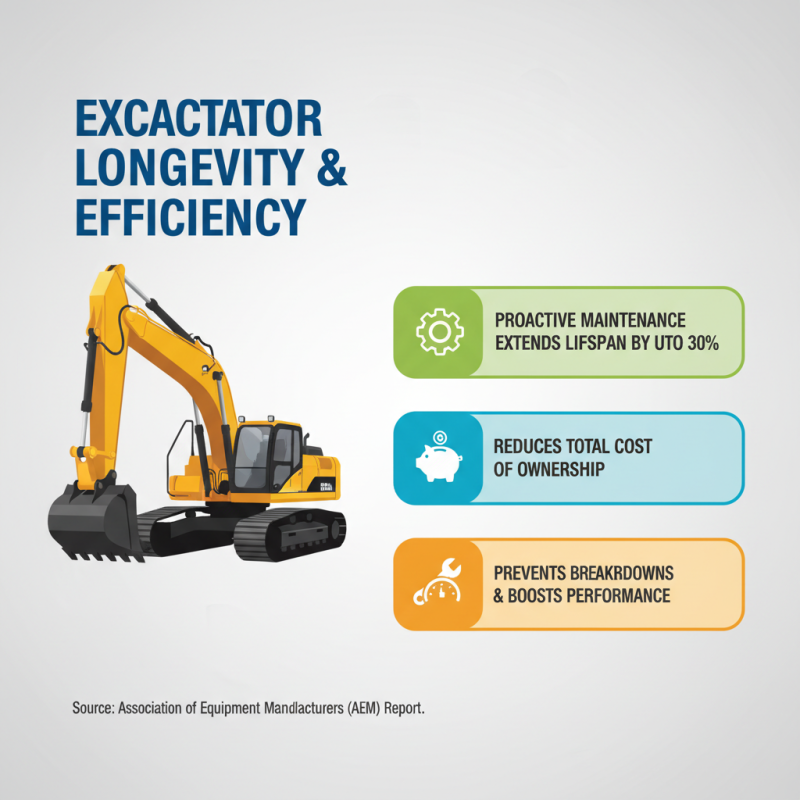

Regular maintenance of excavators is crucial for ensuring their longevity and operational efficiency. According to a report by the Association of Equipment Manufacturers (AEM), proactive maintenance can extend the lifespan of heavy machinery by up to 30%. This means that investing time and resources in routine checks and upkeep can significantly reduce the total cost of ownership over the equipment's life cycle. Proper maintenance not only prevents unexpected breakdowns but also enhances performance, ensuring that excavators operate at their peak efficiency when needed the most.

In addition, a study conducted by the Construction Industry Institute (CII) highlights that companies employing a structured maintenance program see a marked decrease in downtime, with an average reduction of 15-20% in operational delays. Keeping excavators in optimal condition involves timely oil changes, regular inspections of hydraulic systems, and monitoring wear on critical components. Moreover, data suggests that firms that adhere to a strict maintenance schedule report higher resale values for their machinery, further cementing the notion that diligent care pays off in the long run. By comprehensively understanding and prioritizing maintenance, excavator operators can ensure that their investments yield the best possible returns.

Regular inspections are essential for maintaining the efficiency and longevity of your excavator. Key components to check during these inspections include the hydraulic system, undercarriage, and engine. According to industry reports, a well-maintained hydraulic system can improve operational efficiency by up to 15%. Regularly checking hydraulic fluid levels and inspecting hoses for wear and leaks can prevent costly downtime and enhance performance.

The undercarriage should also be a focal point during inspections, as approximately 30% of excavator maintenance costs are associated with wear on tracks and rollers. Monitoring the condition of these components can lead to significant savings, as replacing them prematurely can cost thousands of dollars. Additionally, ensuring that the sprockets and idlers are in good condition can prolong the life of the tracks, contributing to overall equipment reliability.

Lastly, engine maintenance plays a crucial role in ensuring that your excavator operates at peak efficiency. A study indicates that engines maintained regularly can experience up to 20% better fuel efficiency, which translates to lower operational costs. Therefore, periodic checks of oil levels, filters, and coolant systems are vital for extending the life of your excavator while maximizing its performance on the job site. By prioritizing these inspections, operators can achieve substantial gains in both efficiency and equipment longevity.

Maintaining the efficiency and longevity of heavy machinery, such as an excavator, hinges significantly on diligent daily cleaning and maintenance procedures. Start each workday by conducting a thorough inspection of the machine. Check for any visible debris and clear the undercarriage, tracks, and hydraulic components. This prevents the buildup of dirt and materials that can lead to mechanical issues over time. Additionally, ensure that all grease points are properly lubricated to reduce friction and wear during operation.

After each shift, a routine cleaning should be implemented. Use a pressure washer to remove any accumulated dirt, mud, or grime from the machine's surfaces. Pay special attention to areas around the engine and hydraulic systems, as contaminants can compromise performance. It's also beneficial to inspect and clean air filters regularly to ensure optimal airflow to the engine, which is crucial for maintaining performance levels. Consistent adherence to these practices not only enhances the overall reliability of the excavator but also extends its operational lifespan.

| Tip No. | Maintenance Tip | Frequency | Description |

|---|---|---|---|

| 1 | Daily Cleaning | Daily | Remove dirt and debris to prevent corrosion and overheating. |

| 2 | Fluid Levels Check | Weekly | Check oil, fuel, and coolant levels to ensure proper operation. |

| 3 | Inspect Filters | Monthly | Clean or replace air and fuel filters to maintain efficiency. |

| 4 | Grease Joints | Weekly | Lubricate all moving parts to reduce wear and tear. |

| 5 | Check Tire Pressure | Weekly | Ensure tires are inflated to avoid unnecessary strain on the machine. |

| 6 | Inspect Tracks | Every 500 hours | Check for wear and tear to enhance traction and stability. |

| 7 | Hydraulic System Check | Monthly | Inspect hoses and fittings for leaks or damage. |

| 8 | Battery Maintenance | Monthly | Check battery connections and clean terminals. |

| 9 | Examine Safety Features | Monthly | Test alarms and emergency stop buttons. |

| 10 | Schedule Professional Servicing | Annually | Have a qualified technician complete a full inspection and service. |

Optimizing fuel efficiency is crucial for any excavator operator aiming to enhance productivity and reduce operational costs. One of the most effective strategies is to adopt smooth and deliberate operating techniques. Abrupt movements and excessive throttle can lead to higher fuel consumption and increased wear on the machine. Operators should focus on planning their actions, utilizing gradual acceleration and deceleration, and maintaining a steady speed during operation. This method not only ensures better fuel economy but also helps in prolonging the lifespan of critical components.

Additionally, regular maintenance checks play a pivotal role in maintaining optimal fuel efficiency. Ensuring that the excavator is in top working condition can significantly reduce fuel consumption. Regularly inspecting and replacing air filters, checking hydraulic fluid levels, and maintaining proper tire pressure can all contribute to better fuel economy. Moreover, operators should monitor their working environment and make adjustments as necessary; for example, avoiding excessive idling and operating at optimal loads can further enhance efficiency. By integrating these practices, operators can effectively minimize fuel expenses while maximizing the performance of their excavators.

This bar chart illustrates the importance of various operational techniques on optimizing fuel efficiency for excavators. Each bar represents a specific practice along with its estimated impact on fuel consumption.

Scheduling regular professional servicing is essential for maintaining the efficiency and longevity of your excavator. These services not only help identify potential issues before they escalate but also ensure that all components operate at peak performance. Professional technicians have the expertise and tools necessary to diagnose and remedy problems that may not be apparent during routine maintenance checks. This proactive approach can save operators from costly repairs and unexpected downtime.

One important tip for maintaining your excavator is to establish a servicing schedule based on your machine's usage and manufacturer recommendations. Regular inspections can uncover wear and tear that might not be visible during daily checks. Additionally, make sure to keep meticulous records of all servicing and maintenance activities, as this documentation can be invaluable for future reference and when assessing the value of your equipment.

Another critical aspect is to pay attention to the signs of wear—strange noises, reduced performance, or fluid leaks can all indicate that it’s time for professional servicing. By staying attuned to these indicators and not neglecting scheduled services, you can extend the life of your excavator, ensuring it continues to operate efficiently on the job site.