Leave Your Message

- Phone

- E-mail

- Whatsapp

When it comes to choosing the right equipment for your construction or landscaping project, understanding the features of a Sany Mini Excavator can make all the difference. These compact machines are specifically designed to navigate tight spaces while delivering powerful performance, making them an ideal choice for various applications. Whether you're digging trenches, lifting heavy materials, or grading surfaces, a Sany Mini Excavator offers versatility and efficiency that can significantly enhance productivity.

Before investing in a Sany Mini Excavator, it's essential to be informed about the key features that set them apart from other compact excavators on the market. From advanced hydraulic systems to user-friendly controls, these machines come equipped with innovative technology that can help operators maximize their capabilities. Understanding these features not only aids in making an educated purchase decision but also ensures you can leverage the full potential of the excavator in your specific tasks. In this article, we will explore the top 10 essential features of Sany Mini Excavators that every potential buyer should know, helping you to choose the perfect model for your needs.

When considering the purchase of a mini excavator, understanding the key design elements is crucial for making an informed decision. Mini excavators are praised for their versatility and compact size, making them ideal for urban projects where space is limited. Key features to look for include the operating weight, which typically ranges from 1 to 10 tons. An optimal weight allows for stability on uneven terrain while providing lifting power for various tasks. Additionally, the size of the excavator’s digging arm and bucket plays a significant role in its performance; larger buckets enhance efficiency, particularly in bulk material handling, while a longer digging arm facilitates deeper excavation.

Another essential consideration is the excavator’s hydraulic system. A robust hydraulic system ensures better digging force and faster cycle times, which can significantly impact productivity. According to industry reports, machines equipped with advanced hydraulic technology can increase operational efficiency by up to 30%. Furthermore, look for models with ergonomic controls that reduce operator fatigue, as this can lead to longer working hours and improved output on job sites.

**Tip:** When evaluating potential models, it’s advantageous to consult specifications and operational data to ensure alignment with your project requirements. Prioritize machines with adjustable tracks for stability on varied terrain, and consider options for attachments that expand your excavator's capabilities. Always test the machinery in real-world conditions to gauge its performance firsthand.

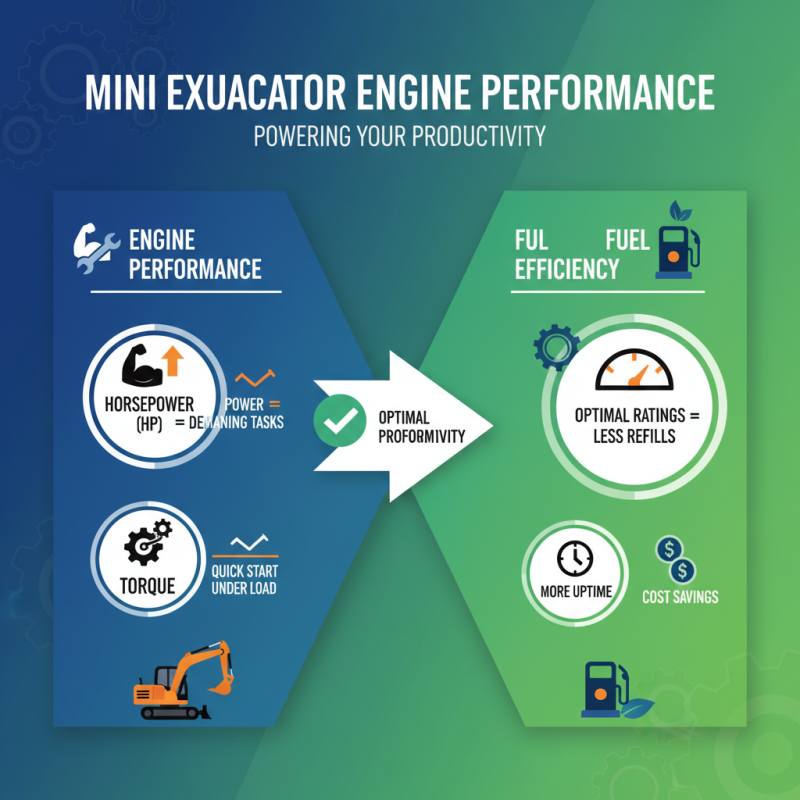

When considering a mini excavator, understanding engine performance ratings and fuel efficiency is crucial. Engine performance ratings typically refer to horsepower and torque, which significantly influence the excavator's ability to handle various workloads. Higher horsepower indicates a more powerful engine, enabling the excavator to perform demanding tasks with ease. Torque, on the other hand, determines how quickly the machine can start moving under load. For contractors and landscapers, choosing a model with optimal performance ratings ensures that the excavator can efficiently tackle different job sites without the frequent need for fuel refills.

Fuel efficiency is another critical factor that should not be overlooked. An excavator with excellent fuel efficiency can significantly impact operating costs, especially for businesses that need to run equipment for extended hours. Comparing the fuel consumption rates of various models helps in identifying efficiencies that could translate into savings over time. Some machines may feature advanced engineering designs or technologies that enhance fuel efficiency while maintaining reliable performance. This attribute ensures that users can maximize productivity without excessively raising operational expenses, making it a key feature to evaluate during the buying process.

When considering a mini excavator, the hydraulic system is a crucial element that significantly impacts both performance and efficiency. Hydraulic systems are responsible for providing the power necessary to lift and move heavy loads, as well as operate attachments like buckets and augers. An efficient hydraulic system uses hydraulic fluid under pressure to transfer energy, allowing for swift and precise movements. According to a recent industry report published by the Association of Equipment Manufacturers, excavators equipped with advanced hydraulic systems can increase productivity by up to 30%, allowing operators to complete tasks more quickly and with greater accuracy.

One essential feature to look for is the hydraulic flow rate, typically measured in gallons per minute (GPM). Higher flow rates enable the simultaneous operation of multiple attachments, boosting overall functionality. For example, mini excavators with a flow rate of 18 GPM or more can handle larger buckets and tools efficiently, thereby enhancing versatility on the job site. Additionally, understanding the system's pressure rating is vital; optimal pressure ranges from 2,500 to 4,500 PSI for many mini excavators, allowing for robust performance across various tasks.

Tips: Always check for adjustable hydraulic settings; they can optimize performance based on specific requirements. Regular maintenance of the hydraulic system is equally important; clean filters and fluid levels ensure efficiency and prolong equipment life. Investing in a model that supports easy access to hydraulic components can simplify repairs and service, a factor that can save time and money in the long run.

When considering a mini excavator, the safety features that enhance operator protection and comfort are paramount. According to a report by the Occupational Safety and Health Administration (OSHA), over 30% of equipment-related incidents occur due to operator error or inadequate safety measures. Therefore, features such as ROPS (Roll Over Protective Structures) and FOPS (Falling Object Protective Structures) are essential to mitigate risks. These safety systems ensure that even in the event of a tip-over or falling debris, the operator remains protected, significantly reducing the likelihood of injury.

In addition to structural safety, modern mini excavators often incorporate user-friendly controls and ergonomic designs to enhance comfort. A study from the International Journal of Industrial Ergonomics highlighted that ergonomic considerations can improve operator efficiency by up to 20%. Features such as adjustable seating, intuitive joystick controls, and climate control systems contribute to a more comfortable working environment, helping to minimize fatigue during long hours on the job.

Tips: Before purchasing, ensure to check for certification marks indicating compliance with safety standards. Additionally, it is beneficial to test the excavator's visibility and accessibility features ensure you can operate it effectively while maintaining a high level of safety. Investing in a model with advanced safety features not only protects the operator but can also lead to increased productivity on the job site.

When considering a mini excavator, one of the most compelling features is the versatility of attachments that can be used. Mini excavators are designed to perform various tasks across diverse job sites, and coupling them with the right attachments significantly enhances their functionality. For instance, industry reports indicate that over 65% of excavator users believe that having a range of attachments increases the machine's return on investment (ROI). Popular attachments, such as buckets, breakers, and augers, allow operators to efficiently tackle tasks ranging from landscape grading to demolition work, thereby maximizing productivity.

Moreover, the adaptability of Sany mini excavators to various attachments contributes to their appeal in both commercial and residential construction. According to a recent market analysis, the mini excavator attachment market is projected to grow at a CAGR of 5.8%, reflecting the increasing demand for multifunctional equipment. This versatility not only helps in reducing equipment downtime but also minimizes the need for multiple machines on the job site, streamlining operations and saving costs. Users can easily switch attachments, ensuring the excavator remains a valuable asset in unpredictable working environments.