Leave Your Message

- Phone

- E-mail

- Whatsapp

Heavy Equipment Machinery plays a crucial role in various industries, including construction, mining, and agriculture. The efficient operation and maintenance of this machinery are essential not only for maximizing productivity but also for ensuring safety and longevity. Understanding the best practices in handling and maintaining these powerful machines can significantly enhance their functionality and reduce operational costs.

In this guide, we will explore the top 10 tips that can lead to more efficient operations and maintenance of Heavy Equipment Machinery. From regular inspections and preventative maintenance routines to proper operator training and best practices in fueling and storage, each aspect contributes to optimal performance. By implementing these strategies, operators can minimize downtime, reduce wear and tear, and extend the lifespan of their equipment, ultimately leading to a more streamlined and effective workflow. As industries continue to evolve, so do the technologies and practices associated with Heavy Equipment Machinery, making it imperative for operators to stay informed and proactive.

Heavy equipment machinery plays a vital role in construction, mining, and other industries, making it essential to understand the different types and their features for effective operation and maintenance. According to the Equipment Leasing and Rental Association, the U.S. construction equipment market was valued at approximately $26 billion in 2022, highlighting the significance of these machines in driving productivity and efficiency. Equipment types range from bulldozers and excavators to cranes and backhoes, each designed for specific tasks. For instance, bulldozers are ideal for grading and pushing heavy materials, while excavators excel in digging and material handling due to their hydraulic capabilities.

Understanding the unique features of each machine can lead to enhanced operational efficiency. A report by the Association of Equipment Manufacturers (AEM) indicates that proper selection and utilization of heavy equipment can improve productivity by up to 30%. For example, wheel loaders, with their versatility, are critical for loading materials quickly in various settings, whereas compactors are essential for soil and asphalt compaction in road construction. Knowledge of these nuances not only aids in choosing the right equipment for a task but also informs maintenance practices, thereby extending the lifespan and reliability of the machinery. Regular maintenance schedules, as suggested by industry experts, can reduce the risk of breakdowns, ensuring that operations run smoothly and efficiently.

Regular maintenance of heavy equipment is crucial for ensuring optimal performance and longevity. According to a report by the Association of Equipment Manufacturers, equipment that is properly maintained can operate up to 20% more efficiently than neglected machinery. This efficiency translates into significant cost savings in fuel consumption and reduced downtime, which can ultimately affect a company’s bottom line. A proactive maintenance strategy, which typically includes routine inspections and timely repairs, not only enhances operational efficiency but also minimizes the risks of unexpected breakdowns.

In addition to operational efficiency, regular maintenance directly impacts safety on job sites. The Occupational Safety and Health Administration (OSHA) highlights that the majority of workplace accidents involving machinery can be attributed to improper maintenance. By adhering to a consistent maintenance schedule, companies can mitigate these risks, protect their workforce, and avoid costly liabilities. Furthermore, a study by the National Institute for Occupational Safety and Health indicates that organizations that prioritize maintenance practices see a 30% reduction in incident rates. Such statistics emphasize the integral role that regular equipment maintenance plays in fostering a safe and productive work environment.

Effective operation and maintenance of heavy equipment machinery is crucial for maximizing both efficiency and safety on the job site. One of the key operational techniques is to ensure that all operators are thoroughly trained and familiar with the machinery they’ll be using. Regular training sessions should incorporate updates on best practices, safety protocols, and new technologies. This continuous education helps operators to handle machinery effectively, reducing the likelihood of errors that can lead to accidents or equipment damage.

Another fundamental technique for enhancing efficiency is the implementation of a regular maintenance schedule. This includes daily checks of fluid levels, wear and tear on parts, and proper calibration of equipment settings. By identifying potential issues before they escalate, operators can minimize downtime and costly repairs. Additionally, maintaining a clean and organized work environment contributes significantly to safety and operational efficiency. A clutter-free workspace allows for better visibility and access, which not only speeds up tasks but also fosters a safer environment for all employees on site.

| Tip Number | Tip Description | Key Benefits | Maintenance Frequency |

|---|---|---|---|

| 1 | Regular Inspection of Equipment | Identifies potential issues before they become major problems | Daily |

| 2 | Proper Operator Training | Ensures safe and effective operation | Upon Hire & Annually |

| 3 | Routine Lubrication | Reduces friction and wear on moving parts | Weekly |

| 4 | Regular Fluid Checks | Maintains optimal performance and prevents overheating | Weekly |

| 5 | Safe Load Handling Practices | Minimizes risk of accidents | Ongoing |

| 6 | Adherence to Manufacturer Guidelines | Ensures longevity and reliability of equipment | As Needed |

| 7 | Efficient Fuel Management | Reduces operational costs | Daily |

| 8 | Clear Communication on Site | Enhances safety and productivity | Ongoing |

| 9 | Use of Quality Replacement Parts | Prevents premature failure and costly repairs | As Needed |

| 10 | Scheduled Maintenance Checks | Keeps machinery in top condition | Monthly |

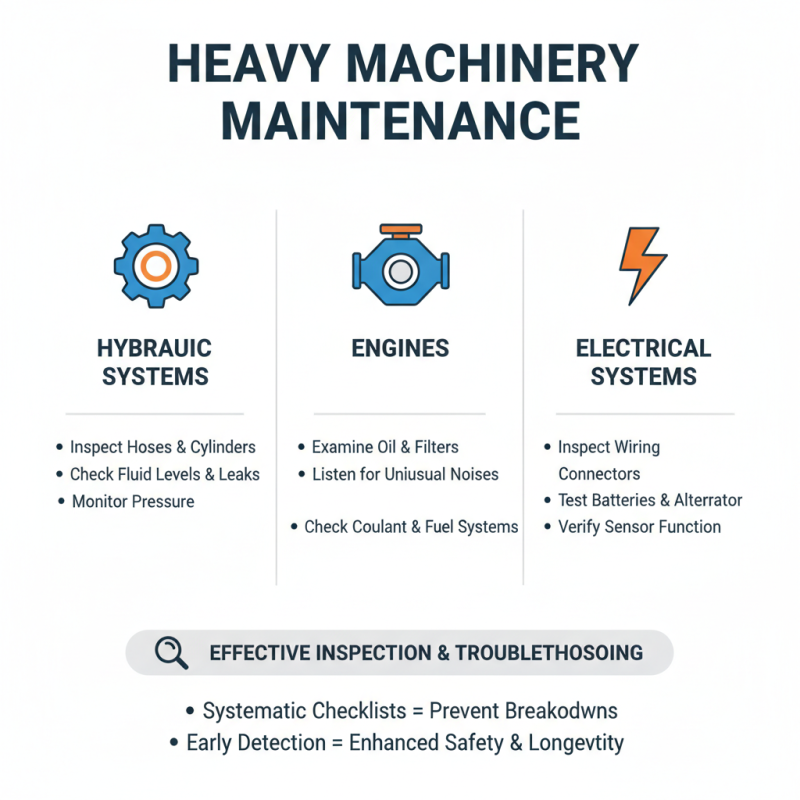

When it comes to maintaining heavy machinery, effective inspection and troubleshooting are vital for ensuring optimal performance and longevity. Regular inspections should be part of any operational routine, focusing on key components such as hydraulic systems, engines, and electrical systems. Technicians should use systematic checklists to examine wear and tear, fluid levels, and functionality. By identifying early signs of potential issues, operators can prevent costly breakdowns and enhance safety on the job site.

Troubleshooting is another critical aspect of maintaining heavy equipment. Operators need to familiarize themselves with common symptoms of malfunction, such as unusual noises, decreased performance, or warning lights. Utilizing diagnostic tools can aid in pinpointing specific problems more accurately. It is also beneficial to develop a habit of documenting any issues and repairs performed, contributing to a history that can inform future maintenance decisions. In addition, collaboration with experienced personnel can provide valuable insights into resolving complex machinery issues more effectively.

Training and certification are critical components in ensuring that heavy equipment operators are equipped with the necessary skills to operate machinery safely and efficiently. Comprehensive training programs should cover both theoretical knowledge and practical skills, allowing operators to gain a deep understanding of equipment functionality and safety protocols. Certification from recognized bodies not only enhances the credibility of the operators but also ensures adherence to safety standards that protect lives and property.

To maintain efficiency in operation, operators should always prioritize proper pre-use inspection of equipment. This includes checking fluid levels, brakes, and safety devices to prevent breakdowns. Additionally, operators should be trained to recognize signs of wear and tear, enabling them to conduct timely maintenance and avoid costly repairs. Regular training sessions can also reinforce the importance of adhering to operational guidelines and safety regulations, ultimately improving both productivity and safety on site.

Another crucial tip for efficient operation is to cultivate a habit of clear communication with crew members, especially when operating larger machinery. Effective communication can prevent accidents and ensure everyone is aware of the equipment's movement and operational status. Fostering teamwork through collaborative training exercises can significantly enhance the overall safety and efficiency of heavy machinery operations.