Leave Your Message

- Phone

- E-mail

- Whatsapp

Excavation equipment plays a crucial role in construction and earth-moving projects. This machinery is specifically designed for digging, moving, and manipulating soil and other materials. It varies widely, from backhoes to excavators and bulldozers. Each type has distinct features and uses, making them essential for different jobs.

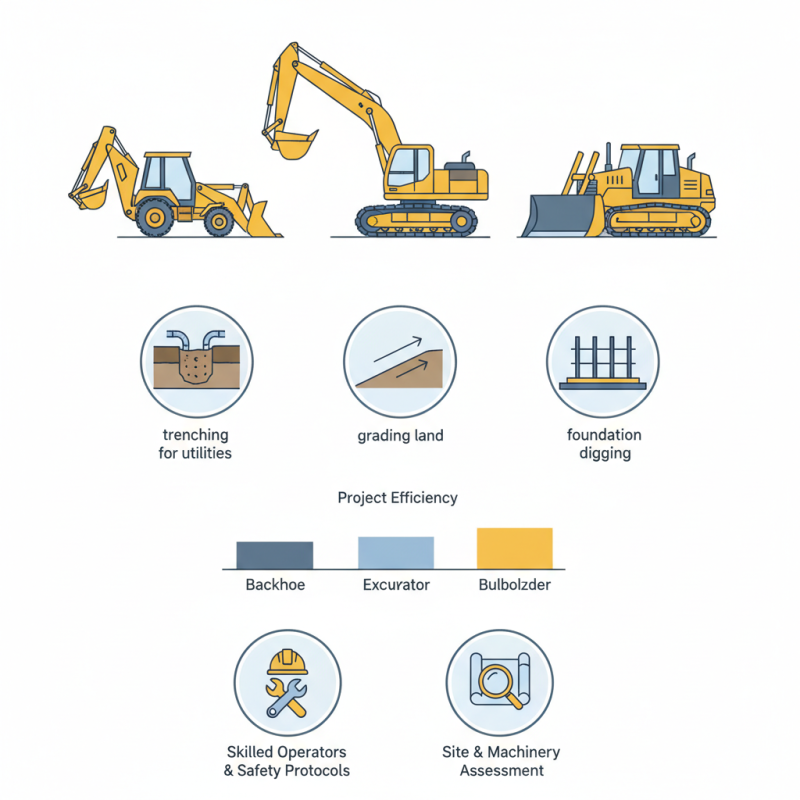

Construction sites often involve complex tasks that require efficient excavation equipment. This equipment helps in trenching for utilities, grading land, and foundation digging. However, the choice of equipment can impact project efficiency. Understanding the specifications and limitations of each machine is vital for optimal use.

Despite its importance, there are challenges in using excavation equipment. Operators must be skilled and aware of safety protocols. There can be a learning curve for new operators, leading to potential errors. It is essential to assess the site and machinery properly before work begins. The right equipment ensures that projects are completed on time and within budget.

Excavation equipment is crucial in construction. It plays a vital role in preparing sites for various projects. Excavators, bulldozers, and backhoes are essential tools in this field. According to industry reports, the global construction equipment market is projected to reach $192 billion by 2025. This growth underscores the importance of efficient excavation equipment.

Using the right equipment can significantly improve productivity. For instance, using a hydraulic excavator can reduce project time by up to 20%. However, improper usage can lead to delays and increased costs. Construction teams need to ensure that operators are well-trained. Regular maintenance of machinery is also essential to enhance performance.

Tips: Always inspect equipment before use. Check for any wear and tear. Proper training ensures safety and efficiency. Furthermore, consider environmental factors when planning excavation. Adverse weather can impact timelines. The more prepared the team is, the smoother the operation will be.

| Equipment Type | Description | Common Uses | Importance |

|---|---|---|---|

| Excavator | A heavy construction machine that consists of a boom, stick, bucket, and cab on a rotating platform. | Digging trenches, material handling, and demolition. | Crucial for large-scale earthmoving tasks. |

| Bulldozer | A tracked vehicle equipped with a wide blade used to push large quantities of material. | Land clearing, grading, and moving soil. | Essential for shaping the terrain before and during construction. |

| Backhoe Loader | A versatile piece of equipment that combines a front loader with a rear digging bucket. | Excavating, loading, and landscaping. | Highly versatile, making it ideal for smaller jobs and projects. |

| Skid-Steer Loader | A compact machine that has lift arms to which a wide variety of attachments can be mounted. | Site preparation, excavating and snow removal. | Highly maneuverable, great for tight spaces. |

| Trencher | A type of heavy equipment used to dig trenches, particularly for pipelines. | Plumbing, electrical, and drainage installations. | Allows for efficient trenching without large scale disruption. |

Excavation equipment plays a vital role in various construction projects. Different types serve specific purposes, making it essential to choose the right one. For instance, backhoes combine the features of a loader and an excavator. They dig, lift, and transport materials efficiently. A compact excavator is perfect for tight spaces, making it a favorite for small residential projects.

Skid steers and mini excavators are other common types. Skid steers are versatile and ideal for landscaping, while mini excavators handle both tight spaces and dense soil. Each piece of equipment has its own advantages and limitations. Understanding these details can be a game changer for project success.

Tips: Always ensure operators are well-trained. Improper use can lead to accidents. Regularly check equipment for wear and tear. Maintenance is key to longevity. Also, consider the soil type before choosing equipment. Different materials can affect performance drastically. Remember, not all projects need heavy machinery. Sometimes, smaller, specialized tools work better.

Excavation equipment plays a crucial role in construction and landscaping. Understanding how this equipment operates can enhance efficiency and safety on job sites. Most common types include excavators, backhoes, and bulldozers. Each serves a specific purpose, from digging and moving material to grading land.

Excavators are designed for digging deep holes. They have a long arm with a bucket at the end. The operator controls it using joysticks. The bucket can scoop up dirt, rocks, and debris. The key is to maintain balance to avoid tipping. It's essential to be aware of the ground stability while working with them.

Tips: Always inspect equipment before use. Check for leaks and wear. Make sure to wear safety gear like helmets and gloves.

Backhoes are versatile. They can dig, lift, and load. The front bucket is helpful for smaller jobs. However, users sometimes struggle with precision while digging. It’s important to practice for accuracy.

Tips: Start with shallow digs to get the hang of it. Watch your machine’s stability as you dig.

Every type of excavation equipment requires careful operation. Operators must be trained and vigilant. Distractions can lead to accidents. Taking time to understand each piece of equipment improves performance and safety.

Safety is paramount when using excavation equipment. Each piece of equipment poses unique risks. Operators must wear appropriate personal protective equipment, such as helmets, gloves, and high-visibility vests. This gear helps mitigate injuries in case of accidents.

Before starting work, a site inspection is essential. Check for overhead power lines, deep holes, and unstable ground. Operators should maintain a safe distance from the excavation edge. These precautions can prevent accidents from happening. Remember, ignoring these steps could lead to serious consequences.

Proper training is crucial for operators. They need to understand their machine's specific functions and limitations. It's surprising how many overlook this training. Regular maintenance checks can also prevent malfunctions that might endanger workers. Making safety a priority creates a more secure work environment, which benefits everyone involved.

Proper maintenance of excavation equipment is essential for longevity. Regular checks on hydraulic systems can prevent costly repairs. Operators should inspect hoses for leaks and cracks. Cleaning the machine after use removes dirt and debris that can cause wear.

Lubrication is crucial for moving parts. Not enough grease can lead to excessive friction. It's easy to overlook, but this step can extend the lifespan of equipment. Operators should follow the service schedule. Ignoring it can result in unexpected breakdowns.

Training employees on proper use and care is vital. Poor handling can damage machinery quickly. Regular training sessions can improve awareness. Keeping manuals handy for reference is also a good practice. Adapting maintenance routines based on equipment age can provide insights. Every piece of equipment has its nuances. Understanding them can ensure better performance over time.