Leave Your Message

- Phone

- E-mail

- Whatsapp

Choosing the right machinery can make or break your project. Sany Machinery offers a range of options that cater to different needs. To make an informed decision, consider several key factors.

Quality is paramount when selecting Sany Machinery. Assessing durability and reliability will save you time and money in the long run. However, not all machines are perfect. Some may fall short in specific tasks. Researching user reviews can help highlight both strengths and weaknesses.

Additionally, think about your project requirements. The specifications of Sany Machinery should align with your tasks. Do you need excavators, loaders, or compactors? Each type serves different purposes. Yet, do not overlook the importance of support services. Sany Machinery can be complex, and having assistance is crucial. Evaluate local dealer networks, service plans, and available parts. This can enhance your overall experience with the machinery.

When considering heavy machinery for your projects, it's crucial to understand the features and benefits they offer. These machines come equipped with advanced technology. This can enhance efficiency in operations. For example, many models include improved fuel efficiency, allowing for lower operational costs. Additionally, they often boast powerful engines that can handle tough jobs effortlessly.

Durability is another key benefit. Well-built machines can withstand demanding environments. This reduces maintenance needs and downtime, which can be a headache for any project manager. However, not all machinery performs the same in every situation. Some may excel in stability while others might lack in overall speed. Understanding these nuances is vital for making an informed choice.

User-friendly controls are also essential. Many machines offer intuitive interfaces, making them easier to operate. This is important for reducing the learning curve for new operators. On the flip side, some models might have overly complex features that can frustrate users. That’s why it's important to check reviews and user feedback. You want reliable machinery that suits your project's specific needs, avoiding steep learning challenges.

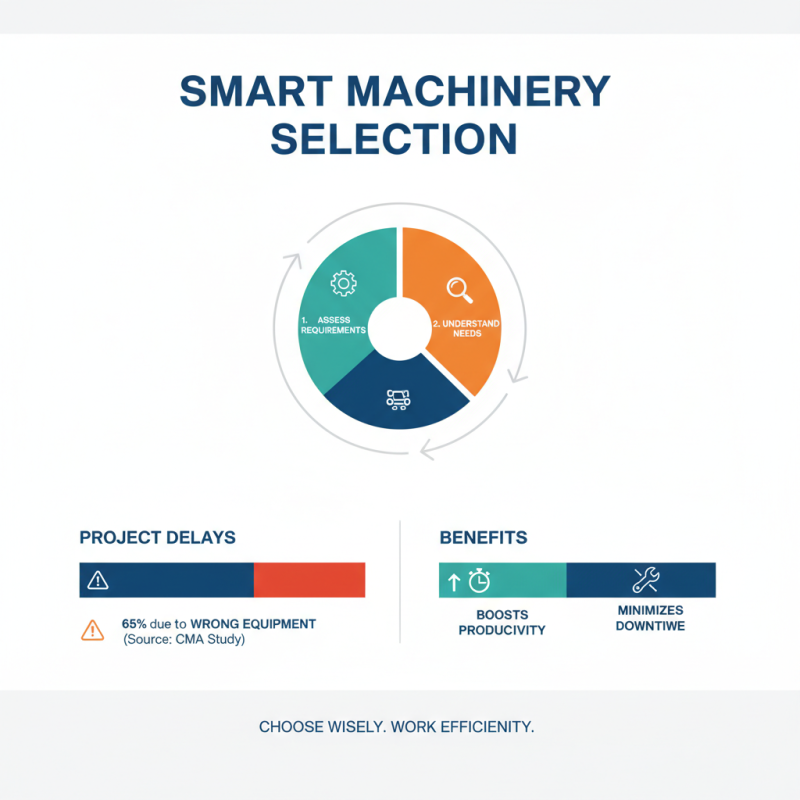

Before selecting machinery for your project, assessing your requirements is crucial. Understanding the specific needs can lead to better decisions. A study from the Construction Machinery Association indicates that 65% of project delays stem from improper equipment selection. Efficient machinery not only boosts productivity but also minimizes downtime.

Consider the project scope. Large-scale projects may require heavy-duty machinery, while smaller tasks might only need compact equipment. For example, a report by Industry Analysis Group notes that 70% of companies that matched machinery to project size reported successful completion on schedule. Think about the terrain, materials, and working conditions as well. These factors influence equipment performance significantly.

It’s essential to evaluate operator skill levels too. Machinery that’s too complex may frustrate inexperienced operators. This could result in accidents or damage. An industry survey highlights this issue, revealing that 30% of mishaps occur due to lack of training for specific machinery. Balancing these factors will lead to more efficient project execution and better resource management.

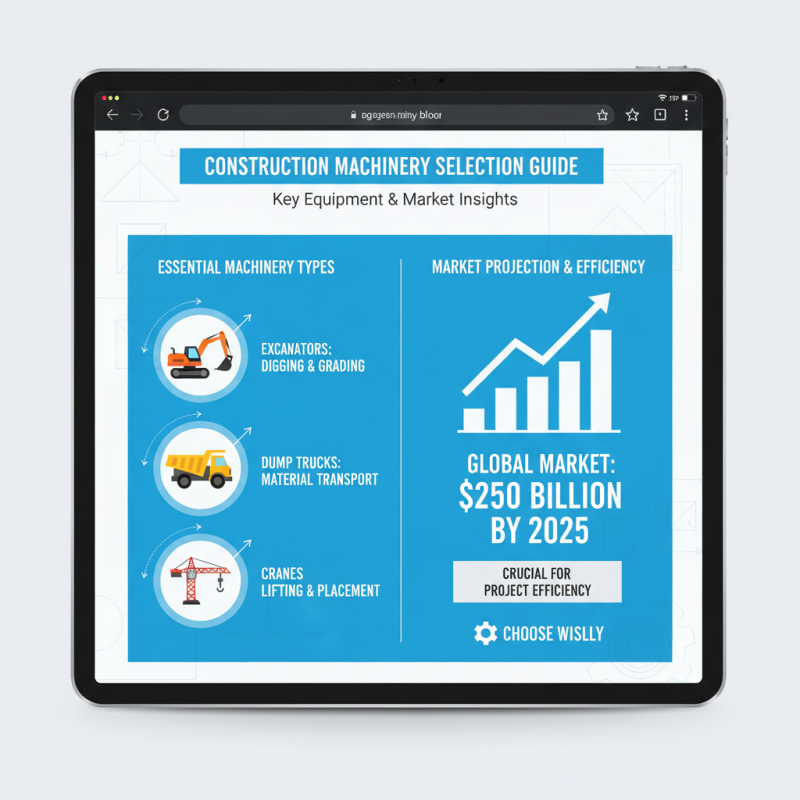

When selecting machinery for construction projects, understanding the available options is crucial. The market offers a diverse range of machinery tailored to various applications. For instance, excavators are essential for digging and grading. According to industry reports, the global construction equipment market is projected to reach $250 billion by 2025. This highlights the importance of choosing the right equipment to ensure project efficiency.

Tips to consider when evaluating machinery options: Analyze your project requirements. Are you working on a small site or a large construction area? Each size demands different machinery capabilities. Research the specifications of various models. This ensures you find equipment that aligns with your needs. It's not uncommon to overlook key features. Always check fuel efficiency and maintenance costs before deciding.

Another aspect to weigh is the machinery's resale value. Some models depreciate faster than others. Lack of awareness in this area can lead to financial losses. Understand the total cost of ownership, including parts and service. A cheaper initial price can lead to regrettable long-term expenses if not studied carefully. Consider these factors thoroughly to make a well-informed decision.

When considering equipment for your projects, budgeting plays a crucial role. It's easy to overlook costs beyond the initial purchase price. Maintenance and operation costs should also be factored in. Poor budgeting can lead to overextending your finances. This can result in equipment that strains your project's budget.

Evaluate your project needs carefully. Different tasks require diverse machinery capabilities. Sometimes, a cheaper model may not meet your requirements. This could lead to inefficiencies and higher costs in the long run. Consider the lifespan and resale value of the equipment as well. A higher upfront investment might save money later.

Creating a flexible budget is essential. Prices can fluctuate due to market demands. Reserve funds for unexpected expenses. It often happens that unplanned costs arise. Balancing quality and cost can be tricky, so take the time to reflect on your choices. Make decisions that not only fit your current budget but also align with your long-term goals.

| Equipment Type | Purchase Cost ($) | Maintenance Cost/Year ($) | Fuel Efficiency (liters/hour) | Resale Value ($) |

|---|---|---|---|---|

| Excavator | 80,000 | 1,500 | 15 | 40,000 |

| Loader | 75,000 | 1,200 | 12 | 37,500 |

| Bulldozer | 85,000 | 1,800 | 16 | 42,500 |

| Crane | 120,000 | 2,000 | 20 | 60,000 |

| Forklift | 30,000 | 800 | 8 | 15,000 |

Maintenance and support services are crucial when selecting machinery for projects. Proper upkeep extends the lifespan of equipment. Industry reports indicate that regular maintenance can increase efficiency by up to 30%. For heavy machinery, this can lead to significant cost savings over time.

Having access to reliable support services is vital. Delayed repairs can halt projects and inflate budgets. According to recent surveys, nearly 70% of equipment failures arise from a lack of maintenance. Consistent maintenance schedules should not be underestimated. They can prevent unplanned breakdowns, which can be costly and disruptive.

However, many operators overlook these services. Some may believe they can manage without them. This mindset can lead to bigger issues down the line. It's essential to weigh the initial savings against potential long-term costs. Investing in maintenance and support can be the difference between a successful project and a failed one. Regular audits of machinery can also identify areas for improvement, ensuring optimal performance at every stage of your project.