Leave Your Message

- Phone

- E-mail

- Whatsapp

Heavy Equipment Movers play a crucial role in various projects. They ensure the safe transport and installation of large machinery. According to John Smith, an industry expert with over 20 years of experience, "The right equipment movers can make or break your project timeline." His insight underscores the importance of choosing skilled professionals.

Moving heavy equipment involves risks and challenges. Delays can lead to increased costs. Improper handling can damage the equipment. Heavy Equipment Movers are trained to navigate these obstacles effectively. They use specialized tools and techniques to ensure safety.

However, not all movers are created equal. Some lack the necessary experience or equipment. This can result in mishaps that could have been avoided. Companies must carefully evaluate their options. Working with experienced Heavy Equipment Movers can enhance project success and minimize potential setbacks.

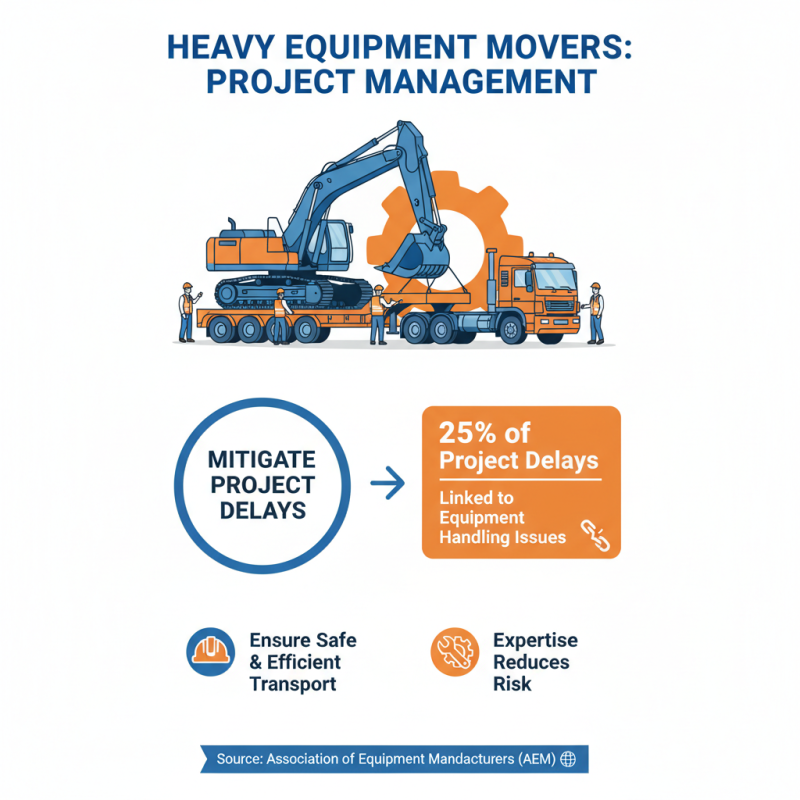

Heavy equipment movers play a crucial role in project management. Their expertise ensures that large and heavy machinery is transported safely and efficiently. A report by the Association of Equipment Manufacturers (AEM) highlights that 25% of project delays are linked to equipment handling issues. Proper movers can mitigate this risk significantly.

Logistics is complex. Every movement of equipment must be planned meticulously. For instance, a crane can weigh over 200 tons. Transporting it involves precise calculations and specialized vehicles. According to industry data, improperly managed equipment relocation can lead to damages exceeding $200,000. Preventing such costly mistakes is where heavy equipment movers prove their value.

The efficiency of a project often depends on how well equipment is managed. Miscommunication can occur, leading to potential project setbacks. Heavy equipment movers help bridge these gaps. They ensure that every piece of machinery arrives on time. Delays in equipment delivery can halt progress and inflate budgets. In fact, research indicates that timely equipment relocation can improve project timelines by up to 30%.

Heavy equipment movers play a critical role in construction and manufacturing projects. According to a report by the Occupational Safety and Health Administration (OSHA), nearly 1 in 10 construction workers is injured each year. Professional movers help mitigate these risks. They understand safety protocols deeply and protect workers on-site.

These movers possess specialized equipment. Cranes, dollies, and trailers are standard tools. They can handle loads exceeding 100 tons. The efficiency of trained professionals often saves time. In fact, a study from the Construction Industry Institute shows that proper logistics can reduce project delays by up to 30%. When every minute counts, having experts on your side makes a difference.

Hiring heavy equipment movers can also save you money. Incorrect handling can lead to damage. This could cost thousands in repairs. According to industry data, businesses lose an average of $8,000 due to equipment downtime. A professional team mitigates such risks. However, it’s important to assess the team’s credentials. Not all services guarantee the same level of expertise. Quality matters when it comes to moving heavy machinery.

Moving heavy equipment can seem manageable, but the risks involved are significant. Many try to handle this task alone, thinking they can save money. However, the potential dangers often outweigh the savings. Without the right knowledge, heavy machinery can cause serious injuries. Accidents happen when proper precautions are ignored.

Heavy equipment is unwieldy and requires expertise to transport safely. Insecure loads can shift during transit. This might lead to damage, delays, or worse. Improper handling can injure workers and bystanders. There’s also the risk of property damage. Even minor mistakes can have costly consequences.

Hiring professionals minimizes these hazards. Experts understand how to navigate challenging situations. They use appropriate tools and strategies. Trusting your project to trained movers not only protects your assets but also ensures crew safety. Consider the long-term benefits of professional help over a misguided attempt at DIY.

| Risk Factor | Description | Mitigation Strategy | Estimated Cost of Risk | Professional Assistance Required |

|---|---|---|---|---|

| Equipment Damage | Improper handling can lead to equipment breakage or wear. | Hire trained movers with proper equipment. | $2,000 - $10,000 | Yes |

| Safety Hazards | Risk of injury to workers during the move. | Use experienced movers and proper safety equipment. | Potential lawsuits or medical costs | Yes |

| Regulatory Compliance | Failure to follow local transport regulations. | Consult professionals familiar with regulations. | Fines can range from $500 to $10,000 | Yes |

| Delays | Unplanned delays that can impact project timelines. | Create a detailed plan and timeline with professionals. | Cost of delays can vary greatly | Yes |

Heavy equipment movers play a crucial role in various projects. According to a recent industry report, using professional movers can reduce project timelines by up to 30%. This efficiency allows businesses to meet deadlines without compromising safety. The same report highlights that companies save approximately 20% on overall costs when hiring experts.

When heavy machinery is handled incorrectly, delays occur. Data shows that improper lifting or transportation can lead to costly damages, sometimes exceeding 15% of project budgets. A survey of construction managers revealed that 40% experience setbacks due to improper equipment handling. This not only affects time but also impacts profitability.

Moreover, relying on professional movers enhances safety. Statistics indicate that construction sites with trained movers see a 50% decrease in accidents involving heavy machinery. This demonstrates that investing in expert services not only streamlines operations but also protects the workforce. Companies must consider these factors to improve their project outcomes.

When selecting heavy equipment moving services, you need to consider several vital factors. Start by assessing the company’s experience. This can make a significant difference. Look for movers who have handled jobs similar to yours. Experience in your specific type of project matters.

Tips: Check their track record. Ask for case studies or references. It helps to know their challenges and successes. A well-experienced team often navigates unexpected issues better.

Next, focus on equipment. Ensure the moving company has the right tools for the job. Outdated or insufficient equipment can lead to delays. Check if they use specialized rigs or heavy-duty trailers. This ensures your equipment is moved safely.

Tips: Verify the condition of their moving equipment. Poorly maintained machines can cause accidents. Research their safety protocols as well. Safety should always be a priority.

Finally, think about communication. The best moving services maintain clear, consistent communication. You need updates throughout the process. Unclear communication can lead to confusion and delays.

Tips: Establish a point of contact. Regular check-ins can help stay informed. Be open about your expectations and timelines.