Leave Your Message

- Phone

- E-mail

- Whatsapp

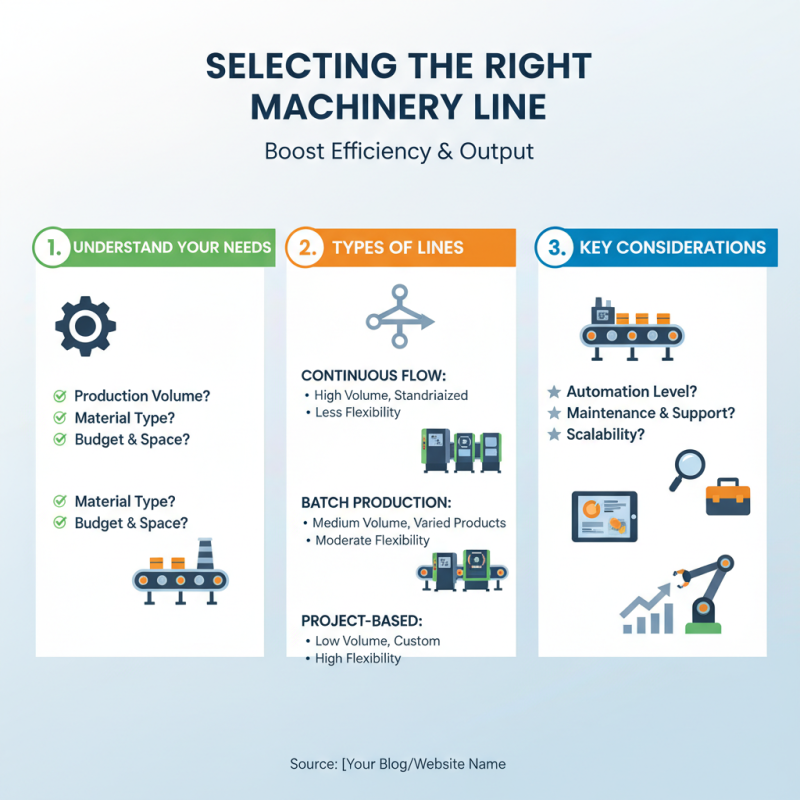

Choosing the right Machinery Line for your business is crucial. The right machinery can significantly impact efficiency, productivity, and overall success. Assessing your specific needs is the first step. Consider the materials you'll work with. Are they heavy or lightweight? This will determine the type of machinery required.

Next, think about your production goals. Do you need high-speed outputs or is precision more important? Each Machinery Line offers different capabilities. Not all equipment serves every purpose effectively. It is essential to evaluate the strengths and weaknesses of various options.

Sometimes, businesses choose equipment without thorough evaluation. This can lead to costly mistakes and inefficiencies. Reflect on your long-term goals. Investing in the right Machinery Line can save time and money. Explore your choices carefully to ensure a successful outcome.

Choosing the right machinery line is crucial for your business. Begin by assessing your specific needs. What products are you making? Understanding your production volume is essential. Large orders require different machinery compared to smaller ones.

Next, consider your workforce skills. Do your employees have the right training? If not, additional training may be necessary. This can lead to higher costs initially but can improve efficiency. Think about maintenance as well. Some machines require frequent repairs, while others are more reliable.

Finally, reflect on your long-term goals. Are you planning to expand? If so, choosing scalable machinery can save money and time in the future. It's vital to take a step back and evaluate these aspects critically. Make a detailed plan. This preparation will pay off.

Choosing the right machinery line is crucial. Different types of machinery lines serve various needs. Understanding the options helps businesses operate efficiently.

There are several common types to consider. For example, production lines focus on mass manufacturing. Packaging lines, on the other hand, handle the final stages of product preparation. Maintenance lines are essential for ongoing upkeep and service. Each serves a unique purpose but selecting one requires careful thought.

Not all lines fit every business model. Size, capacity, and cost all play important roles. Assessing your product type can help refine your choice. Sometimes, a line doesn’t meet all needs. This mismatch could lead to delays or added costs. Regular evaluation of machinery effectiveness is vital. It ensures that your choice supports growth rather than hinders it.

Choosing the right machinery line for your business is a critical decision. Evaluating your budget is a key part of this process. Start by determining how much you can invest. Consider both initial costs and ongoing maintenance expenses. This dual focus will help paint a clearer financial picture.

Tips: Look closely at financing options. Some suppliers may offer installment plans. This can ease immediate financial pressure. Also, don’t forget about hidden costs. Training and installation can add up quickly.

Costs can fluctuate widely. It’s valuable to compare multiple quotes. Don't rush the decision. Take your time to evaluate the long-term benefits of each option. Sometimes, spending more upfront can lead to savings later.

Tips: Keep an eye on resale value. Equipment with higher demand can boost your return. Make sure to assess warranties and support as well. A strong warranty can save you money down the road. Remember, the cheapest option might not always be the best one.

Choosing the right machinery line can be daunting. Understanding your space and operational needs is crucial. You need to assess your facility layout. Consider the height, width, and length of your area. Can the machinery fit comfortably? If it’s too cramped, efficiency will suffer.

Look at your workflow. How will products move through the space? Identify potential bottlenecks. Are there corners that may hinder movement? Optimize machine placement to ensure smooth operations. This requires planning and sometimes multiple drafts. Don't rush to a decision; revisit your layout.

Flexibility is key for any business. You might grow or change processes. Anticipate these shifts when choosing machinery. A machine that seems perfect now may not fit future needs. This calls for reflection and adaptability. Plan now, but keep the future in mind.

| Machinery Type | Space Requirement (sq ft) | Operational Requirement | Output Capacity (units/hour) | Power Consumption (kW) |

|---|---|---|---|---|

| CNC Milling Machine | 200 | Requires skilled operator | 50 | 5 |

| Injection Molding Machine | 300 | Automatic operation possible | 120 | 15 |

| Laser Cutting Machine | 400 | Requires trained technician | 25 | 10 |

| Robotic Arm | 250 | Flexible programming | 30 | 7 |

| Conveyor System | 150 | Minimal manpower needed | 200 | 3 |

When selecting machinery for your business, researching suppliers is crucial. Look for companies that have established reputations. Read reviews and testimonials from other businesses. Personal experiences often reveal more than brochures. Consider reaching out to existing clients. Ask about their experiences and satisfaction with the supplier's reliability.

After-sales support can be a game changer. A supplier that offers strong support can mitigate future issues. Inquire about warranty details and service availability. Understand response times for service calls. It's a challenging journey to find dependable assistance. Sometimes, support options can seem limited. Reflect on how much downtime could impact your operations. The right partner can make maintenance easier and reduce stress.