Leave Your Message

- Phone

- E-mail

- Whatsapp

In today's competitive landscape, the selection of the right Machinery Line has emerged as a pivotal factor in determining a business's success. As reported by the Global Machinery Industry Analysis, the market is projected to grow at a CAGR of 5.2% from 2021 to 2026, underscoring the increasing reliance on advanced machinery for operational efficiency and productivity. A well-chosen Machinery Line not only optimizes production cycles but also minimizes downtime, leading to significant financial returns.

As industry expert Dr. Emily Chen states, "Investing in the appropriate Machinery Line is not merely a choice; it is a strategic decision that directly impacts efficiency and long-term profitability." Her insights resonate with many business leaders who recognize that the machinery they implement plays an essential role in maximizing output and sustaining their competitive edge. Consequently, understanding the nuances of various Machinery Lines is critical for decision-makers aiming to align their operations with future market demands and technological advancements.

The machinery line selected by a business plays a pivotal role in its operational efficiency and overall success. According to a report from the International Journal of Production Research, about 30% of production inefficiencies can be attributed to inadequate machinery and outdated equipment. This highlights the importance of choosing machinery that not only meets the current demands of the production line but is also adaptable to future technological advancements. Investing in the right machinery ensures that businesses can maintain a competitive edge by optimizing their processes and reducing downtime, which accounts for approximately 5-10% of total production costs, according to data from the Manufacturing Institute.

Moreover, the integration of advanced machinery can lead to significant improvements in product quality and safety standards. A study conducted by the National Institute of Standards and Technology revealed that companies utilizing cutting-edge machinery reported a 15% reduction in defect rates and a corresponding increase in customer satisfaction. This quantifiable impact on quality underscores how the right machinery line can enhance not only internal processes but also customer relations, ultimately driving profitability. Understanding these dynamics is essential for business leaders who strive to make informed decisions that align with their long-term strategic goals.

Choosing the right machinery is essential for businesses looking to enhance productivity and efficiency. Various industries have distinct needs that dictate the type of machinery suitable for their operations. For instance, the manufacturing sector requires machinery that not only meets production quotas but also maintains a high level of precision to minimize waste and ensure product quality. According to a report from the International Federation of Robotics, a 10% increase in robotics deployment in manufacturing can lead to a 15% boost in productivity. This highlights the importance of selecting machinery that aligns with specific operational goals.

In industries such as agriculture, the machinery chosen can directly impact yield and labor efficiency. The American Society of Agricultural and Biological Engineers reported that implementing advanced machinery like precision planters and automated irrigation systems can increase crop yields by up to 25%. This data emphasizes that evaluating the right tools is not just a matter of convenience, but a critical factor in maximizing output and maintaining competitiveness. By thoroughly assessing the specific needs of their industry and adopting the appropriate machinery, businesses can make informed decisions that foster growth and success.

| Machinery Type | Industry | Key Features | Typical Application | Estimated Cost ($) |

|---|---|---|---|---|

| Excavator | Construction | Versatile, high lifting capacity, tracks for stability | Earthmoving, digging trenches | 80,000 - 200,000 |

| CNC Machine | Manufacturing | Automated precision, programmable, multi-axis | Metalworking, intricate part fabrication | 20,000 - 500,000 |

| Forklift | Warehousing | Lifting capacity, maneuverability, operator-friendly | Material handling, storage logistics | 25,000 - 50,000 |

| 3D Printer | Additive Manufacturing | Layer-by-layer construction, rapid prototyping | Prototype creation, custom parts | 2,000 - 300,000 |

| Compressor | Construction & Manufacturing | Air pressure output, portable, diesel/electric options | Powering pneumatic tools | 1,500 - 20,000 |

When selecting machinery for your business, several key factors play a critical role in ensuring long-term success and operational efficiency. First and foremost, understanding your production needs is vital. According to a report by the Association for Manufacturing Technology, nearly 70% of manufacturers experience disruptions due to inadequate equipment that cannot keep up with production demands. Thus, conducting a thorough assessment of your production capacity, workflow, and future growth projections can guide you in choosing machinery that aligns perfectly with your specific operational requirements.

Another significant consideration is the total cost of ownership (TCO), which encompasses not only the initial purchase price but also maintenance, energy consumption, and downtimes. A study by Deloitte highlights that businesses that factor TCO into their machinery selection can reduce overall costs by up to 30%. This analysis should also include the machine's lifecycle, as investing in high-quality, durable equipment can yield better returns over time and minimize unexpected repair costs. Additionally, reviewing supplier support and warranty options is essential; reliable service can drastically reduce production interruptions and enhance operational reliability.

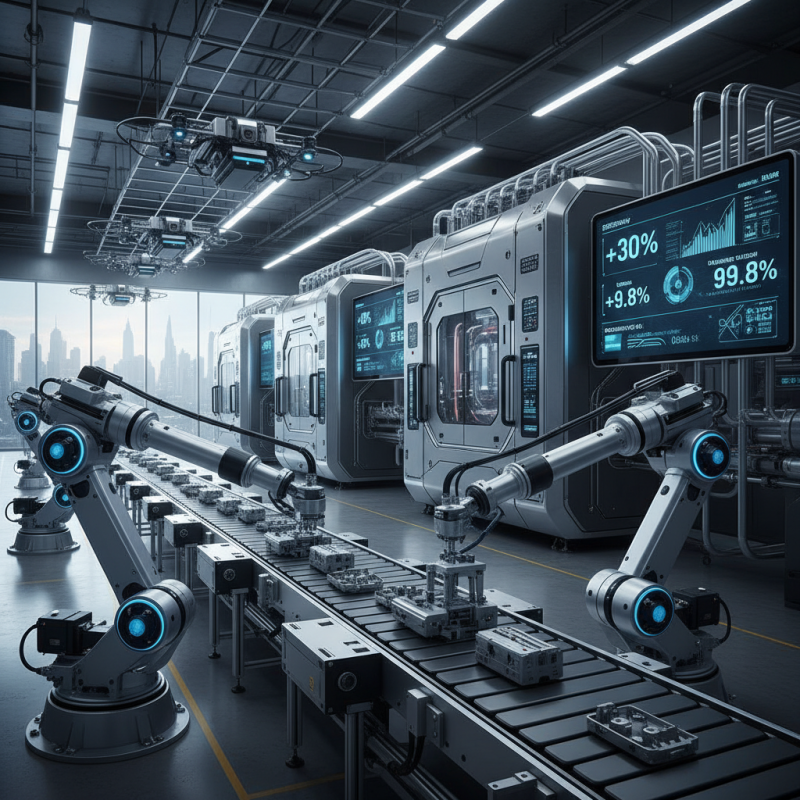

The role of technology in enhancing machinery efficiency and performance cannot be overstated. In today’s competitive business landscape, companies that leverage advanced technologies in their machinery are often the ones that gain a significant edge. Automation, data analytics, and the Internet of Things (IoT) are just a few examples of how modern technology can streamline operations, reduce downtime, and optimize production processes. For instance, IoT-enabled machinery can provide real-time data regarding performance metrics, allowing businesses to make proactive adjustments and improve overall efficiency.

Moreover, the integration of smart technologies facilitates predictive maintenance, which minimizes the risk of unexpected machine failures. By utilizing sensors and machine learning algorithms, companies can analyze usage patterns and foresee potential malfunctions before they disrupt operations. This not only saves time and resources but also enhances the reliability and lifespan of the machinery. As technology continues to evolve, investing in the right machinery equipped with the latest innovations becomes crucial for maintaining high performance and achieving long-term success in any industry.

Investing in the right machinery line is essential for sustaining long-term growth in any manufacturing business. According to a report by MarketsandMarkets, the global industrial machinery market is expected to grow from $745 billion in 2020 to $1,045 billion by 2025, highlighting the significant demand for advanced machinery solutions. Selecting the right equipment not only enhances operational efficiency but also minimizes downtime and maintenance costs, which can significantly impact a company’s bottom line. Research by McKinsey & Company indicates that businesses that invest in innovative machinery see a 20-30% increase in overall productivity compared to those that rely on outdated equipment.

Moreover, the benefits of choosing the appropriate machinery extend beyond immediate operational improvements. A report from the International Federation of Robotics suggests that companies leveraging automation and advanced machinery report higher employee satisfaction and retention rates. This is largely due to reduced monotonous tasks and enhanced worker safety, leading to a more engaged workforce. Additionally, the initial investment in advanced machinery can lead to substantial long-term savings. Studies show that businesses adopting energy-efficient machinery can reduce their energy costs by up to 25%, further contributing to sustainable growth and profitability. Therefore, the strategic selection of machinery not only fosters operational success but also equips businesses to adapt to future challenges and market demands.