Leave Your Message

- Phone

- E-mail

- Whatsapp

Choosing the right Hitachi Excavator is crucial for any construction project. The perfect model can impact your productivity and efficiency. Hitachi offers a range of excavators, each designed for specific tasks. It’s important to assess your project's demands before making a decision.

Consider the scale of your worksite. A smaller project may need a compact excavator for tight spaces. Larger sites often require a heavy-duty model. Understanding the conditions you will work in can help. A machine that excels on rough terrain might not perform well in urban environments.

Budget is another key factor. Hitachi Excavators come in various price ranges. Sometimes, opting for a used model can be beneficial. However, ensure any used equipment has been well maintained. Reflect on your choices thoroughly before purchasing. A well-chosen excavator can lead to greater efficiency, while a hasty decision may lead to regrets later.

Choosing the right excavator for your project involves several key factors. Understand the nature of your work site. Is the ground stable or rocky? Different models excel in various terrains. A lightweight excavator may suffice for soft soil, but you need heavier machinery for tougher conditions.

Evaluate the size of your project. A smaller job might not require a large machine. Yet, opting for one that is too small could slow down your progress. Think about the attachment options as well. Some models offer flexibility with attachments like buckets and hammers, enhancing their versatility on the job site.

Consider your budget and operating costs. Larger excavators often demand more fuel and maintenance. Reflect on the long-term expenses versus the initial purchase price. Make sure to account for operator experience as well. Inexperienced operators may struggle, even with the right equipment. Balancing these factors is essential when making your decision.

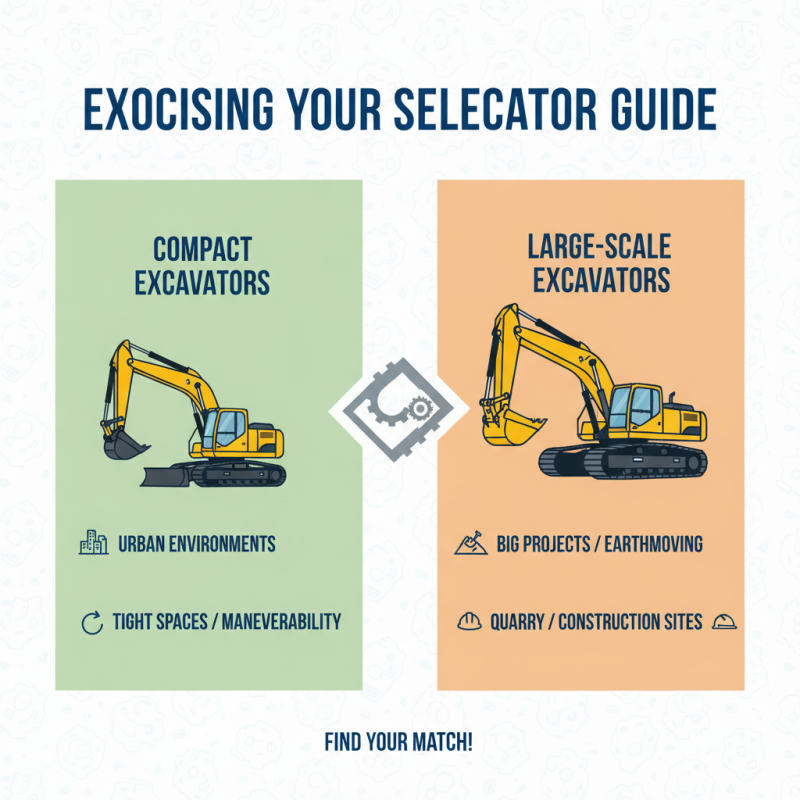

When considering the right excavator model for your project, it's vital to explore the various options available. Different models cater to diverse needs. For instance, some are designed for compact spaces, while others might be more suitable for large-scale operations. Compact excavators are ideal for urban environments. Their smaller size allows for easier maneuverability.

On the other hand, larger models offer greater lifting capacity and stability. They excel in heavy-duty tasks like digging foundations or moving large materials. Understanding the specifications of each excavator is crucial. Not all models come equipped with the same features. Some might lack advanced technology or fuel efficiency promised by newer designs. It's essential to weigh these factors against your project's demands.

You might feel overwhelmed by choices. Take time to review each model's strengths and weaknesses. Don’t forget to consider the terrain and project duration. Reflect on past projects; what worked? What didn’t? Sometimes the latest model isn't the best fit. A well-suited excavator can save time and costs. Always consider the specific needs of your project before making a final decision.

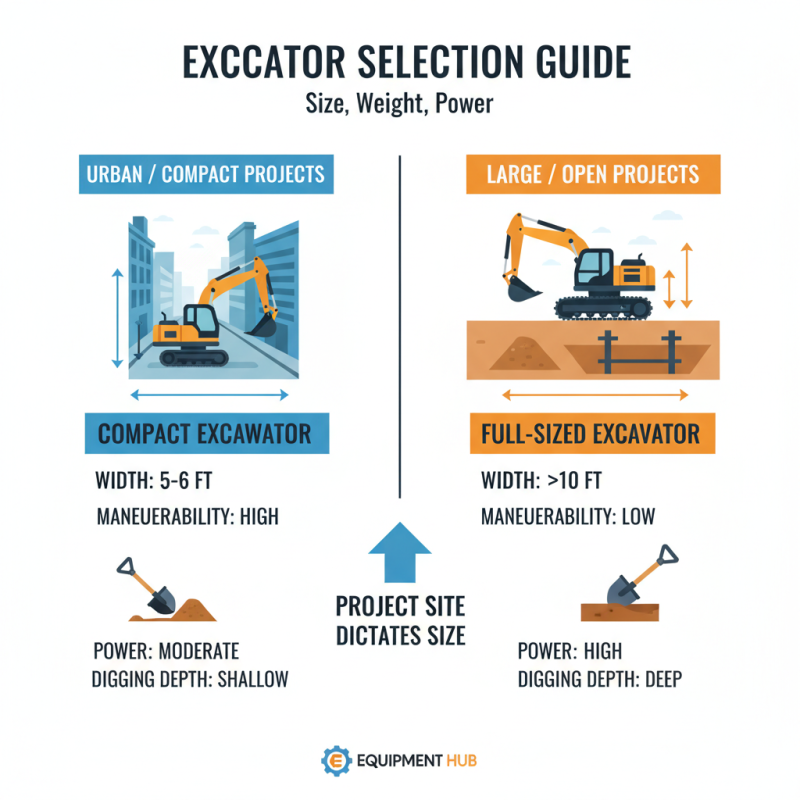

When choosing an excavator for your project, evaluating size, weight, and power is crucial. The project site often dictates the necessary size of the equipment. For tight urban spaces, a compact excavator with a width of around 5 to 6 feet can be a better fit. On the other hand, larger projects may require full-sized models exceeding 10 feet in width, giving more power and digging depth.

Weight is another critical factor. Equipment under 10,000 pounds is suitable for residential jobs. However, heavier models, often exceeding 50,000 pounds, provide greater stability and performance for larger excavations. According to industry reports, excavators in the 20 to 30 ton range are increasingly popular because they balance size and power effectively.

Power needs differ based on soil type and job demands. A project on rocky terrain may require a machine with at least 100 horsepower. Some reports indicate that excavators with adjustable power settings can optimize performance and fuel efficiency. It’s worth reviewing these power settings to avoid underperformance. Balancing these factors can be challenging. Finding the right mix is key to project success, requiring both adequate power and proper equipment handling.

When selecting an excavator for your project, understanding the role of attachments is essential. Attachments can significantly enhance the performance and versatility of your machine. For instance, a hydraulic thumb can improve precision, while a rotating grapple is vital for handling materials. Make sure to explore various attachment options to meet your specific needs.

Choosing the right attachments can be challenging. Different projects may require different tools. This variability can lead to unexpected delays or costs. It’s crucial to evaluate what you need at the start. Talk to others in the industry for insights on what works best in real situations.

Customization options extend beyond attachments. Depending on your project's demands, features like cab comfort and technology integration can improve efficiency. A well-equipped excavator should match the task at hand. Think about your project's duration and the conditions. This reflection can lead to better choices and reduce future complications. Don't rush this decision; clarity will save time and money.

When considering an excavator for any project, budgeting plays a crucial role. The initial purchase price is only part of the total cost. Maintenance, fuel, and insurance can add significantly to expenses. For instance, reports indicate that maintenance can account for up to 20% of the total cost over the life of the machine. Therefore, investing in a reliable model pays off over time.

Beyond purchase costs, fuel efficiency is another major consideration. Many excavators operate at varying fuel rates, impacting long-term expenses. A well-chosen machine can decrease fuel costs by up to 15%. This reduction may seem small, but over years of operation, it adds up significantly. Being aware of these details can prevent unexpected budget overruns.

Additionally, don’t overlook the potential need for attachments or specialized equipment. These can increase initial costs but may enhance versatility on the job site. Workers often find themselves needing different tools, leading to unanticipated expenses. Keeping these factors in mind ensures a more accurate budget. Choose wisely to avoid facing budgetary constraints later.

| Excavator Model | Operating Weight (tons) | Engine Power (HP) | Average Hourly Rental Cost ($) | Fuel Consumption (L/hour) | Recommended Applications |

|---|---|---|---|---|---|

| Model A | 10 | 80 | 150 | 7 | Site Preparation, Landscaping |

| Model B | 15 | 100 | 200 | 9 | Excavation, Demolition |

| Model C | 20 | 120 | 250 | 12 | Heavy Excavation, Mining |

| Model D | 25 | 150 | 300 | 15 | Construction, Large Projects |

| Model E | 30 | 180 | 350 | 18 | Deep Excavation, Trenching |