Leave Your Message

- Phone

- E-mail

- Whatsapp

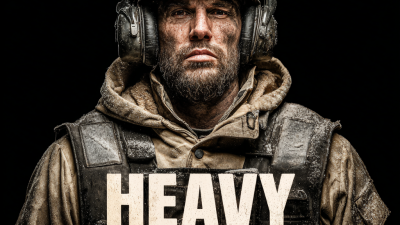

Choosing the right Heavy Machine Operator is a critical decision for any construction project, as the efficiency and safety of operations heavily rely on their expertise and skillset. With the construction industry continually evolving and the demand for high-quality workmanship increasing, it’s essential to find an operator who not only possesses the technical knowledge required to handle complex machinery but also understands the intricacies of the job site. This guide will walk you through the key considerations in selecting a Heavy Machine Operator tailored to your specific construction needs, ensuring that you achieve optimal performance and maintain site safety standards. From evaluating qualifications and experience to assessing soft skills and compatibility with your team, making an informed choice can significantly impact the success of your construction endeavors.

When evaluating heavy machine operators for your construction needs, it is crucial to consider several key factors to ensure safety and efficiency on the job site. The recent incidents involving violations of workplace safety regulations highlight the importance of hiring individuals who not only possess the necessary technical skills but also have a solid understanding of safety protocols. Operators should be well-versed in the operation of heavy machinery and aware of the risks associated with their tasks, particularly in high-risk environments such as construction sites.

Additionally, assessing an operator’s experience is essential. Look for candidates who have a proven track record of operating heavy machinery under various conditions. It is also important to consider their certification and training. Proper certification indicates that the operator has undergone the necessary training to handle machinery safely and effectively. Lastly, soft skills such as communication and teamwork should not be overlooked, as heavy machine operators often work alongside other construction professionals and must be able to convey important information clearly to prevent accidents.

When selecting a heavy machine operator for your construction project, it’s crucial to prioritize certain certifications and qualifications that can guarantee their capability and safety. Key certifications such as the Radio Telephone Operator (RTO) Certificate, established by the Ministry of Civil Aviation, ensure that operators can efficiently manage communication while operating heavy machinery. Additionally, the Operator Certification Program for water and wastewater treatment highlights the importance of specialized training relevant to the construction context, potentially indicating a candidate’s adherence to safety standards.

Tips: When evaluating operators, consider their completion of programs like the ASTM’s Powder Bed Fusion – Laser Beam (PBF-LB) Machine Operator Certification. This specialized training not only demonstrates their technical skills but also their commitment to industry standards. Furthermore, always verify the authenticity of their credentials to avoid hiring candidates with fraudulent certifications, a growing concern in many sectors as seen in the recent cancellations of fake qualifications in Australia.

Tips: When evaluating operators, consider their completion of programs like the ASTM’s Powder Bed Fusion – Laser Beam (PBF-LB) Machine Operator Certification. This specialized training not only demonstrates their technical skills but also their commitment to industry standards. Furthermore, always verify the authenticity of their credentials to avoid hiring candidates with fraudulent certifications, a growing concern in many sectors as seen in the recent cancellations of fake qualifications in Australia.

In today's job market, strong emphasis is also placed on ongoing professional development. Those who pursue safety certification programs, such as Forklift Operator certifications, showcase their dedication to maintaining a safe working environment. Always look for operators who actively seek new certifications; this commitment to personal growth can be indicative of their performance on the job.

When selecting a heavy machine operator for your construction project, experience plays a crucial role in determining the success and safety of operations. A seasoned operator not only understands the intricacies of various machinery but also possesses the skills to handle unexpected challenges that may arise on-site. Their familiarity with different terrains and conditions allows them to make informed decisions quickly, ensuring that the project stays on track and within budget.

Furthermore, experienced operators are often well-versed in safety protocols, reducing the risk of accidents that can lead to costly delays and injuries. They know how to conduct proper pre-operation inspections and are aware of the limits and capabilities of the machines they operate. This knowledge minimizes the likelihood of equipment damage and promotes a safer working environment for everyone involved. Ultimately, hiring an operator with a solid background in heavy machinery operations not only enhances productivity but also fosters a culture of safety and efficiency on your construction site.

| Operator Name | Experience (Years) | Types of Machinery Operated | Certification | Safety Record |

|---|---|---|---|---|

| John Smith | 10 | Excavator, Bulldozer | OSHA Certified | Excellent |

| Sara Johnson | 8 | Backhoe, Forklift | CPR Certified | Good |

| Michael Brown | 12 | Crane, Grader | Heavy Equipment License | Outstanding |

| Emily Davis | 6 | Skid Steer, Loader | First Aid Certified | Very Good |

| David Wilson | 15 | Dump Truck, Paver | Hazmat Training | Excellent |

When selecting a heavy machine operator for your construction projects, assessing their safety record and practices is crucial. According to the Bureau of Labor Statistics, heavy and tractor-trailer truck drivers, a closely related field, reported 6.2 fatalities per 100,000 full-time workers in 2020, highlighting the inherent risks in operating heavy machinery. Therefore, an operator's history of safety incidents can reveal their adherence to protocols and risk management skills, which are paramount on any construction site.

Further, it is essential to evaluate the operator's training credentials and ongoing safety education. Reports from the National Institute for Occupational Safety and Health (NIOSH) indicate that proper training can reduce accidents significantly—by as much as 30% in some environments. Inquire about any certifications, such as OSHA training or specific equipment operator qualifications. Furthermore, engaging in conversation regarding their approach to safety practices—like regular maintenance checks and hazard assessments—can provide insights into their operational mindset. Prioritizing these aspects will not only ensure compliance with safety standards but also foster a culture of safety within your construction team.

Effective communication with your heavy machine operator is crucial for the success of any construction project. According to the Occupational Safety and Health Administration (OSHA), almost 20% of workplace injuries in construction can be traced back to inadequate communication on-site. To minimize risks and ensure smooth operations, establishing clear communication channels is essential. Utilize hand signals, radios, and even digital communication platforms to share information in real time, ensuring that operators are always aware of their surroundings and project requirements.

Additionally, fostering a culture of open dialogue can greatly enhance performance. A survey by the Associated General Contractors of America revealed that 71% of construction professionals believe that improved communication leads to higher work efficiency and safety. Regular briefings before shifts, coupled with feedback sessions, can help address any issues or concerns that operators may have. By prioritizing effective communication strategies, construction teams can reduce delays and enhance teamwork, ultimately contributing to the successful completion of projects.