Leave Your Message

- Phone

- E-mail

- Whatsapp

Choosing the right crawler crane can significantly impact the success of a construction project. According to a report by the International Construction Equipment Association, the global crawler crane market is projected to grow at a compound annual growth rate of 5.2% through 2026. This growth reflects the vital role crawler cranes play in heavy lifting and construction tasks across various sectors.

Expert insight emphasizes the importance of selection. John Smith, a leading crawler crane expert, states, “Choosing the right crawler crane can make or break your project.” This underscores the responsibility project managers have in assessing specific needs, site conditions, and load requirements. Factors such as boom length, lifting capacity, and mobility must align with the project's demands.

Mistakes can lead to costly delays or accidents. Projects may suffer from underestimating the site’s soil conditions, which impacts stability. Accurate assessments are crucial yet often overlooked. Comprehensive evaluations are essential for choosing an appropriate crawler crane. Careful planning and informed decisions will ensure that the right machine is selected for the job.

Crawler cranes play a vital role in construction projects. They are versatile machines used for heavy lifting. When choosing a crawler crane, various factors come into play. The project size and weight of materials are crucial. A small crane may be inadequate for a large task. Conversely, an oversized crane can lead to inefficiencies. It’s essential to assess site conditions as well.

Understanding the ground composition is important. Soft soil may require a more robust crane. Stability is key for safety. The height and reach needed for the project cannot be overlooked. Selecting a crane with appropriate capabilities ensures efficient operations. Safety features should also be a priority.

Budget constraints often complicate the decision. Sometimes, it’s tempting to choose a cheaper option. However, this might lead to higher costs in the long run. Reliability is crucial, so investing wisely is needed. Consider the training of operators too. Skilled personnel can maximize the crane's potential.

When selecting a crawler crane, understanding your project needs is crucial. Start by evaluating the weight of the loads. A heavy load requires a stronger crane. Think about the height and reach needed. Taller structures might demand a crane with extended boom capabilities.

Site conditions also play a critical role. Is the ground stable or soft? If the ground can’t support heavy equipment, you may face challenges. Look at the available space. A cramped site limits maneuverability and operation. Safety considerations should not be overlooked. Proximity to power lines or buildings can impact crane selection.

Finally, consider the project timeline. Some cranes are quicker to set up than others. Delays can lead to increased costs. Team discussions around equipment requirements often reveal overlooked aspects. Reflecting on your requirements early helps avoid missteps later. It’s better to spend time in the initial planning phase than to rush decisions under pressure.

When selecting a crawler crane for your project, several key specifications demand attention. Load capacity is crucial. It determines the weight the crane can lift safely. Consider the maximum load you expect. Ensure the crane meets and exceeds this weight. Stability is another vital factor. A stable crane can prevent accidents. Check the dimensions of the crawler's track and overall width for better stability on uneven terrain.

Moreover, boom length significantly impacts reach. A longer boom allows for lifting materials from greater distances. However, this may compromise maneuverability. It's essential to find a balance between reach and ease of movement. Other features, like counterweights, also affect performance. More counterweights provide greater stability but can complicate transport.

Lastly, don't overlook the environment where the crane will operate. Soft ground or limited space can restrict some models. Assessing the site conditions may lead to a tougher choice than expected. These specifications are intertwined and complex; finding the right fit can be challenging. Being mindful of these elements can lead to more informed decisions.

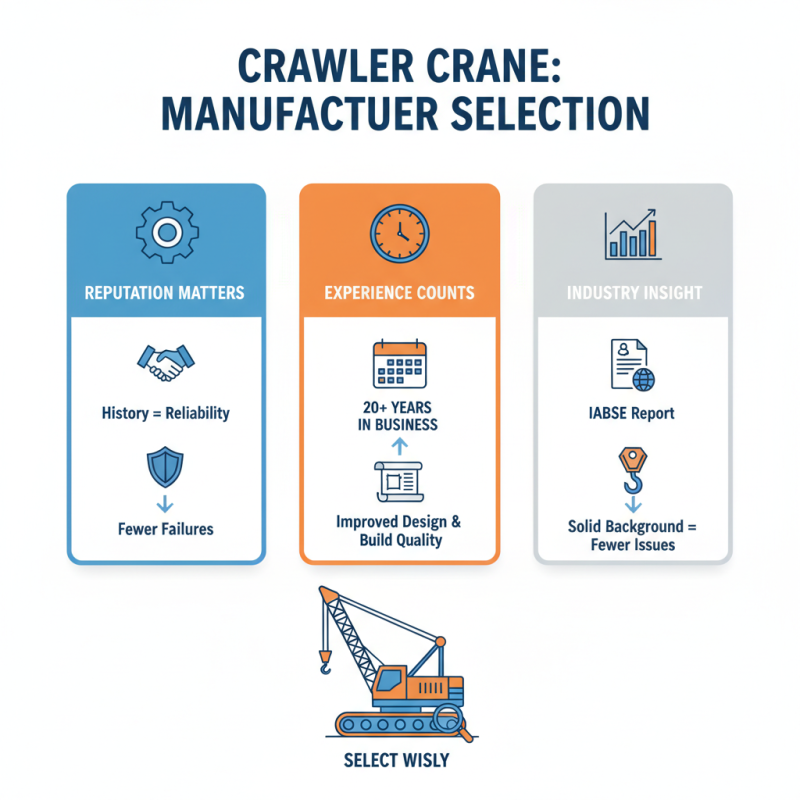

When selecting a crawler crane for a project, assessing the manufacturer’s reputation is key. A manufacturer’s history can indicate the reliability of their products. According to a report from the International Association of Bridge and Structural Engineers, companies with a solid background tend to have fewer failures. Look for those that have been in business for over 20 years. Experience often correlates with better design and construction quality.

Support is equally crucial. A reputable manufacturer provides strong after-sales service. The 2022 Crane Industry Report states that 78% of contractors prioritize manufacturers that offer robust training programs and immediate technical help. A lack of support can lead to downtime, complicating project timelines. Consider manufacturers that invest in customer relationships and provide ample training resources.

Evaluating these factors can be challenging. Not every manufacturer’s claims are verifiable. Often, contractors overlook the importance of reliable support and focus solely on price. It’s essential to balance cost with potential long-term benefits. Sometimes a lower upfront cost leads to higher maintenance fees and support challenges. Conduct thorough research and seek feedback from other contractors. This approach can lead to better decision-making.

When budgeting for a crawler crane, costs can vary significantly. According to industry reports, daily rental rates range from $1,500 to $5,000, depending on the crane's capacity and features. Longer projects may lead to better rental deals. However, renting isn't always cost-effective. If your project spans several months, purchasing might be more economical.

Consider maintenance costs. Crawler cranes require regular upkeep, which adds to overall expenses. Reports suggest that maintenance can account for 10-15% of the equipment's purchase price annually. Additionally, insurance costs for valuable machinery can further strain budgets. Understanding these hidden costs is crucial.

Examining project specifications is essential. Lifting capacity and height play critical roles in crane selection. For instance, if you need to lift 100 tons, a standard model won't suffice. Improper analysis can lead to financial setbacks and project delays. Always perform a thorough cost evaluation before committing to a rental or purchase. This ensures you stay within your budget and meet your project needs effectively.