Leave Your Message

- Phone

- E-mail

- Whatsapp

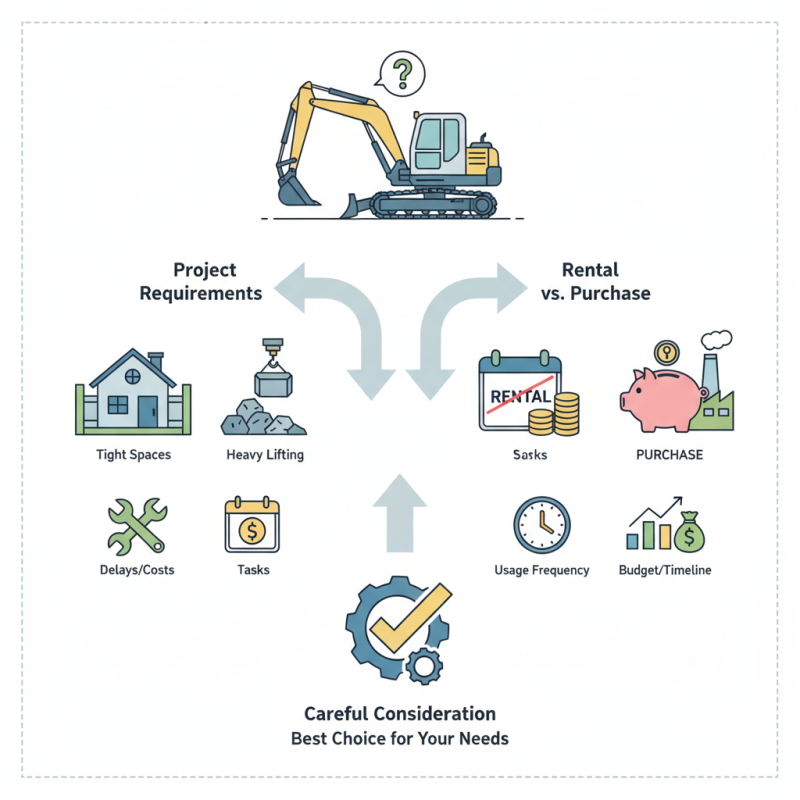

Choosing the right mini excavator for your project can be daunting. Mini excavators are versatile machines, but not all are created equal. They vary in size, power, and features. Knowing what you need is crucial to making the right choice.

Consider your project's requirements carefully. Do you need a mini excavator for tight spaces or heavy lifting? Some models excel at one, but might not handle the other well. It's important to match the machine's capabilities with your tasks. Mistakes in this area can lead to delays and additional costs.

Also, think about the rental versus purchase debate. Rental might seem affordable, but costs can add up. On the other hand, buying a mini excavator requires a significant investment. Reflect on how often you'll use it. This decision can greatly impact your budget and project timeline. Ultimately, careful consideration will guide you to the best choice for your needs.

Choosing the right mini excavator starts with understanding your project requirements. Consider the size of the job site. A compact excavator works well in tight spaces, while larger projects may require a heavier model. According to industry reports, over 60% of contractors find size and maneuverability crucial when selecting equipment. Knowing your project’s layout can help avoid costly mistakes.

Next, evaluate the type of work you'll perform. Digging depth and bucket size are essential factors. For example, if your project involves trenching, choose an excavator that can reach depths of at least 6 feet. Industry studies suggest that using the right bucket size can improve efficiency by up to 20%. Remember, an inadequately sized excavator can cause delays. Reflect on your needs carefully.

You must also assess the terrain. Soft soil demands different machine specifications compared to rocky grounds. A study indicated that many operators underestimate the impact of ground conditions, which can lead to unexpected challenges. Analyze the soil type and select an excavator with the appropriate features, such as tracks for better stability. Misjudging this aspect may complicate operations, leading to delays and increased costs.

Choosing the right mini excavator involves evaluating various sizes and capabilities. Mini excavators come in different weights and dimensions, usually ranging from one to ten tons. Smaller models are ideal for tight spaces, while larger ones offer greater power and load capacity. Think about where you'll use the machine. Will it be on a construction site or in a backyard? Space considerations are crucial.

Digging depths also vary. Some mini excavators can dig down to depths of over ten feet. Others may only reach six feet. Assess the soil conditions. Rocky or clay-heavy soils require more robust machines. If the job involves lifting heavy materials, consider the machine's lifting capabilities. Not all models are equally equipped for heavy lifting tasks.

It's good to reflect on what you truly need. Sometimes you may be tempted by features you don't require. For instance, advanced hydraulic systems may seem appealing but could complicate maintenance. Try to avoid getting caught up in unnecessary extras. Focus on what your specific tasks require. This clarity can lead you to the right choice for your project.

This chart compares the operating weight of various mini excavator sizes, which can help you determine the best fit for your project needs. Consider the weight and capabilities relative to the tasks at hand when making your choice.

When selecting a mini excavator, it's essential to understand the various attachments available. These tools can significantly enhance the machine's versatility. For instance, a hydraulic hammer can break concrete, while a grapple can move debris. Each attachment serves a unique purpose. Choosing the right one depends on your project's specific needs.

Technology also plays a crucial role in modern mini excavators. Features such as advanced hydraulic systems can improve efficiency. Some machines come with GPS for precise grading. However, not all technologies are necessary for every task. It's vital to evaluate if the added tech aligns with your project's goals. Sometimes, simpler options may perform just as well.

Don’t overlook maintenance considerations. Some advanced features require more upkeep. This could lead to additional costs. Reflecting on your operational environment is important. Not every project demands high-tech solutions. A balance between required functionality and operational simplicity can lead to better decision-making.

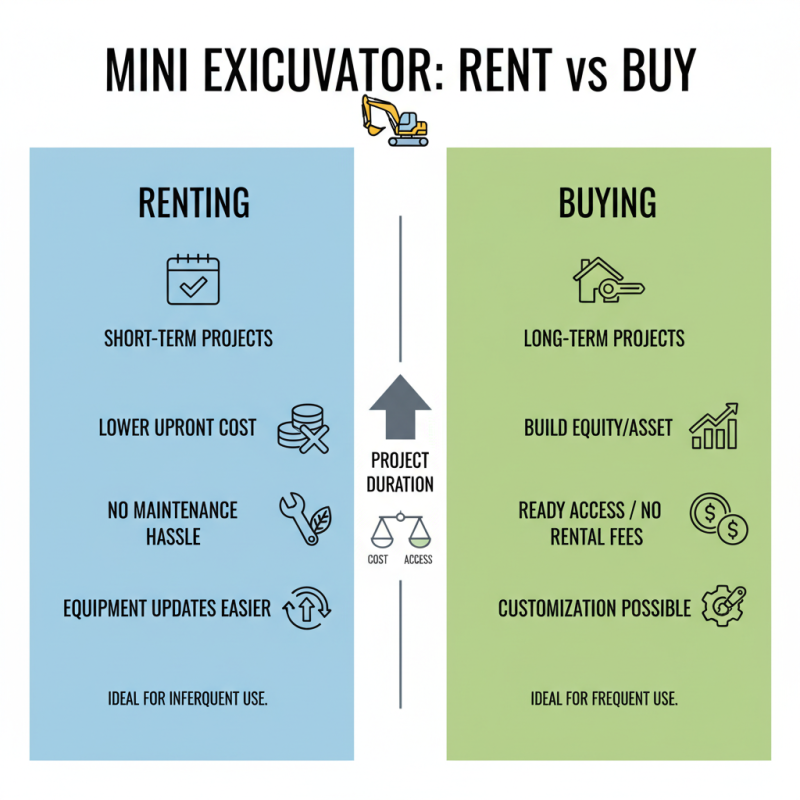

When deciding between renting or purchasing a mini excavator, several factors come into play. Consider the duration of your project. If it's short-term, renting makes sense. You save on upfront costs. However, long-term projects may justify buying. Ownership means no rental fees and predictable access.

Evaluate your budget carefully. Renting can appear cheaper, but costs add up with time. Daily or weekly rental fees accumulate quickly. If you find yourself needing a mini excavator often, purchasing may be wise. You can control maintenance and repairs. This also allows you to avoid delays from waiting for a rental.

Think about the specific tasks involved in your project. Some jobs require a specialized excavator, making rental more attractive. However, if you foresee multiple projects, investing in a versatile machine could pay off. Weigh your options carefully. Each choice has risks and benefits that require reflection.

When budgeting for mini excavator costs, consider both initial and ongoing expenses. The average purchase price for a new mini excavator typically ranges from $20,000 to $50,000. Used options can be more affordable, but they may come with hidden repair costs. Research shows that maintenance can average about $300 to $500 per year. Keeping these numbers in mind helps in planning effectively.

Tips: Always factor in insurance. This can add another $200 to $600 annually. Evaluating these costs against your project's budget is essential. Renting a mini excavator can be a budget-friendly option. Rental fees usually vary between $200 and $600 per day, which might suit shorter projects.

Don’t forget about fuel consumption. A mini excavator can average 1 to 2 gallons of fuel per hour. This adds up, especially during extended work hours. Unplanned breakdowns can be costly too. Avoiding those requires regular maintenance checks, which are often overlooked.