Leave Your Message

- Phone

- E-mail

- Whatsapp

In the construction and logistics industries, choosing the right Heavy Equipment Movers is essential. According to recent reports, the heavy machinery transport market is expected to grow significantly, reaching approximately $15 billion by 2025. This growth highlights the increasing demand for specialized moving services that cater to heavy equipment needs.

Selecting Heavy Equipment Movers involves several considerations. Factors such as load capacity, distance, and safety regulations significantly impact the decision-making process. A poor choice can lead to costly delays and equipment damage. Industry experts emphasize that not all movers are equipped for such tasks.

Reviews indicate that many companies may overstate their capabilities. It’s crucial to look for movers with a proven track record. Heavy Equipment Movers should have the necessary certifications and equipment to ensure safe transportation. Researching options can save time and money, but it can also be challenging. Finding an ideal fit requires careful examination of various alternatives.

Heavy equipment movers play a critical role in various industries, including construction and manufacturing. These movers ensure that large machinery is transported safely, minimizing downtime and risks of damage. According to the American Rental Association, moving heavy equipment incurs costs estimated at $40 billion annually. Choosing the right movers can significantly affect operational efficiency.

Safety is paramount in this sector. Statistics reveal that about 70% of heavy equipment-related accidents occur during transportation. Proper handling reduces the risk of injuries and associated costs. Selection criteria should include the mover's experience, equipment quality, and safety records. A thorough background check helps avoid potential failures.

Many businesses underestimate the importance of investing in experienced movers. Cost-cutting can lead to poor service. An increase in improper handling leads to increased repair costs. This not only affects finances but also impacts project timelines. Research suggests that firms that prioritize quality movers experience up to 30% fewer delays. Investing in reliable heavy equipment movers ultimately contributes to successful project execution.

This bar chart illustrates the average lifting capacity (in tons) and operational efficiency (measured in hours per task) of various types of heavy equipment movers commonly used in the industry. Understanding these metrics can help you determine the best mover for your specific requirements.

When looking for heavy equipment movers, it’s important to understand the types available. The market offers various movers tailored for different needs. Flatbed trailers can transport large machinery easily. They provide a stable platform, ensuring safety during transit. A specialized lowboy trailer is also popular. It has a lower deck, allowing for taller equipment without the risk of hitting bridges.

Forklifts are another essential type. They assist in loading and unloading heavy items. Choose a forklift designed for your specific machinery weight. Otherwise, you might face issues. Crawler tractors also fit the bill. They can move heavy loads across rugged terrain. Their tracks create stability on uneven surfaces, which is crucial.

Tips: Always assess the weight and dimensions of the equipment. This will help in choosing the right mover. Also, inspect the moving equipment for wear and tear. You don’t want a malfunction during a critical move. Lastly, consider the terrain of your project site. Some movers excel in specific conditions but struggle in others. Don't overlook these details; they can save you time and headaches.

| Mover Type | Weight Capacity (tons) | Best For | Key Features |

|---|---|---|---|

| Crawler Transporters | 100+ | Construction Sites | Versatile traction, stable on rough terrain |

| Lowboy Trailers | 25-50 | Heavy Machinery Transport | Low deck height, easy loading and unloading |

| Flatbed Trucks | 10-20 | General Equipment Transport | Flexible loading options, suitable for various sizes |

| Self-Propelled Modular Transport (SPMT) | Up to 100+ | Heavy and oversized equipment | Highly maneuverable, can move in tight spaces |

| Forklifts | 5-15 | Warehouse and Yard Use | Easy to operate, useful for stacking and transporting |

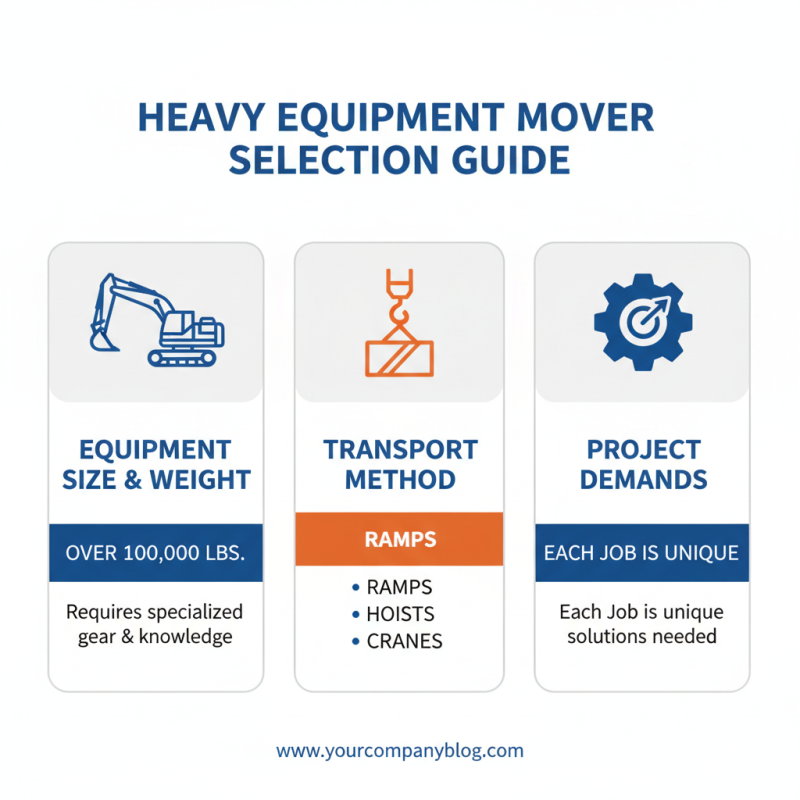

When selecting heavy equipment movers, several factors should be carefully evaluated. The size and weight of the equipment play a significant role. According to industry reports, hauling machinery over 100,000 pounds requires specialized equipment and expertise. Loading ramps, hoists, and cranes can ensure safe transportation. Consider the specific demands of your project. Each job is unique, and general solutions might not suffice.

Experience is crucial in this industry. Look for movers with a proven track record. The better the experience, the fewer issues are likely to arise during transportation. Check for references and previous project case studies to validate their capabilities. This can save time and reduce costs. It’s essential to ask about their safety standards as well. A strong safety record is non-negotiable.

Tip: Always clarify insurance coverage before hiring movers. This will protect you from unexpected costs. Communication is vital. Clearly outline your needs and expectations upfront.

Another consideration is cost. While it may be tempting to choose the cheapest option, weigh the benefits against potential risks. Sometimes, investing a bit more ensures that your equipment is moved safely and efficiently. Don’t rush this decision. Proper planning and research will lead to satisfactory results.

When it comes to transporting heavy equipment, choosing the right mover is essential. You'll want movers that specialize in heavy machinery. They should understand the complexities involved in transportation. Look for companies that provide trained professionals who know how to handle equipment safely.

Consider the type of heavy machinery you own. Different movers have varied expertise. Some may excel in moving excavators, while others focus on forklifts. Check customer reviews to gauge reliability and service quality. Take note of the company’s safety record, too. Mistakes can lead to costly damages.

Don’t forget about logistics. It’s not just about moving from point A to B. Efficient planning involves route assessment, equipment securing, and timely delivery. Communication is also key; stay in touch with the movers during transit. You may encounter unexpected challenges. Being prepared can help alleviate stress.

When budgeting for heavy equipment moving services, understanding the costs involved is crucial. Many companies charge between $100 and $200 per hour for moving services. These rates can vary based on factors like distance, equipment size, and complexity of the move. According to a recent industry report, transport logistics can account for nearly 30% of the total moving costs. This highlights the importance of planning ahead.

Additionally, specialized moving equipment may come with extra fees. These can range from $50 to $500, depending on the equipment type and operational risks. It's important to consider insurance costs as well. Many movers require coverage to protect against damages, which can add 10-15% to your overall budget. Unexpected costs often arise, reflecting potential issues with logistics or equipment integrity.

Negotiating and comparing quotes is essential. A survey revealed that 45% of businesses overspend due to a lack of research. This can result in significant financial strain. Planning and foreseeing potential challenges can mitigate these risks. Refining your moving strategy based on reliable data can lead to better choices. Don't overlook the importance of careful budgeting for a successful equipment relocation.